Mobile: 8613421351153

Cold storage sandwich panel

Cold room panels

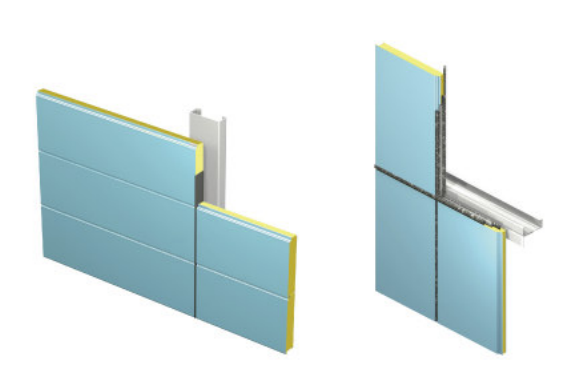

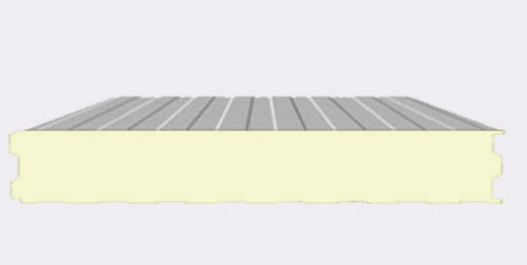

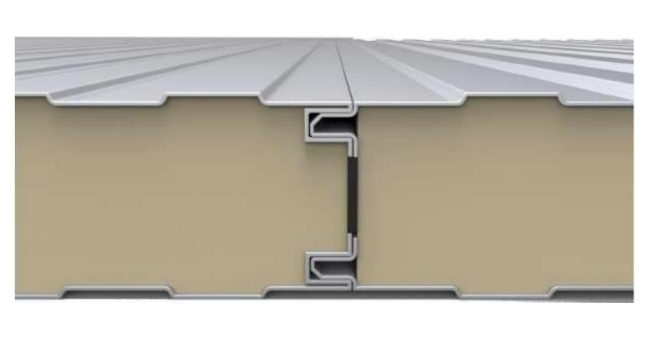

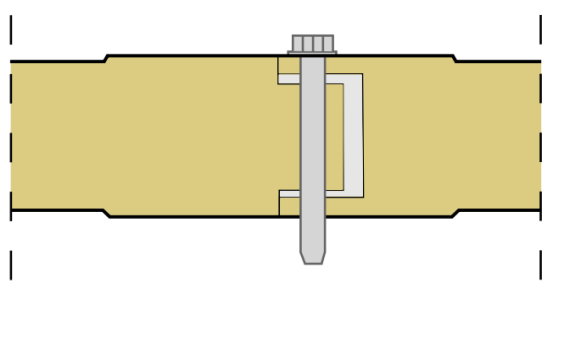

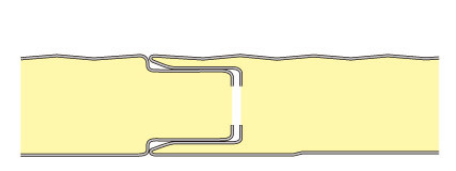

The polyurethane cold room panel has the advantages of flame retardancy , thermal insulation, compression resistance, energy saving and environmental protection. Taking lightweight polyurethane as the inner material of the cold storage panel, the advantage of polyurethane is that the thermal insulation performance is very good. The exterior of the polyurethane cold storage panel is made of color steel plate or stainless steel plate components .

The advantage of this is to prevent the temperature transmission of the cold storage panel due to the large temperature difference between the inside and outside, so as to make the cold storage more energy-saving, The utility model can have the heat preservation effect like a refrigerator, reduce the power consumption and improve the refrigeration efficiency.

Application: applicable to industrial freezers, food freezers, fruit and vegetable controlled atmosphere warehouses, logistics freezers, ultra-low temperature freezers,ship freezers, high and low temperature laboratories, constant temperature rooms, large ski resorts, food purification and processing workshops.clean workshops,drying rooms, etc.

PU Cold Room Panel

Product Features:

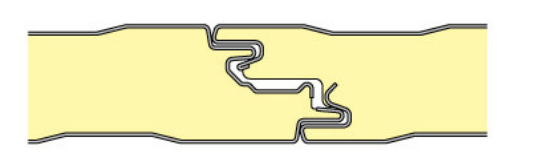

- Lined and flat surface type options

- Pre-painted galvanized steel, stainless steel or PVC film laminated inner and outer sheet alternatives

- Fire performance according to TS EN 13501-1,B2; d0 for PUR insulated cold storage panels,

- Production flexibility at any ordered length between 2 m – 12 m

- Core thickness options 75-100-120-150-180-200 mm

- According to TS EN 14509, U values range between 0,27 – 0,11 W/m2k depending on the panel thickness

- PUR insulation alternatives

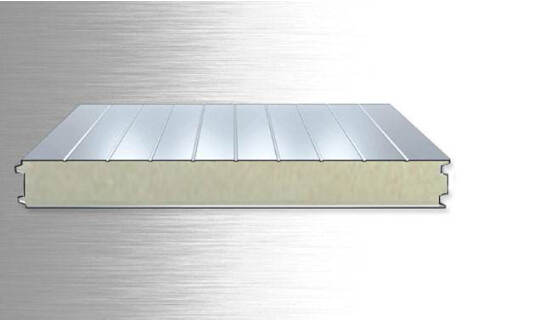

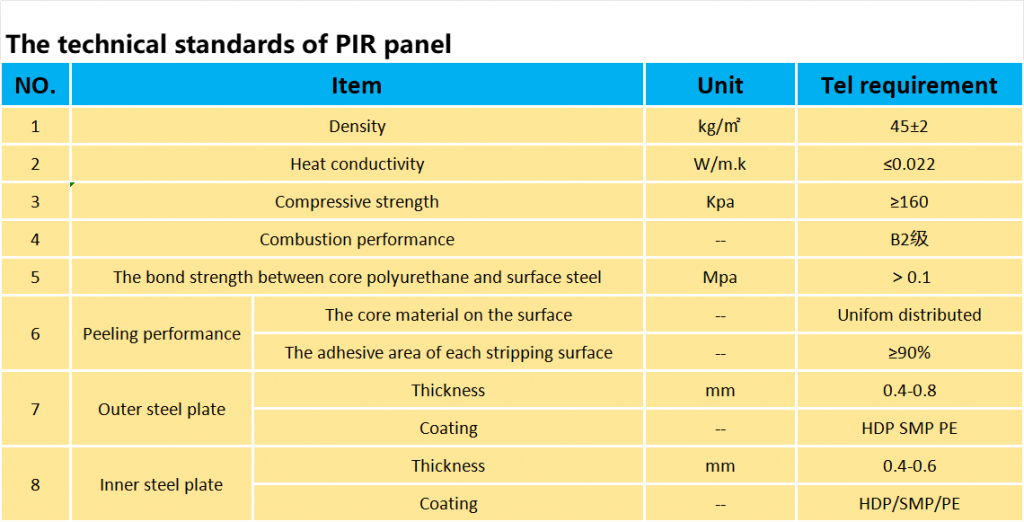

PIR Cold Room Panel

Product Features:

- Lined and flat surface type options

- Pre-painted galvanized steel, stainless steel or PVC film laminated inner and outer sheet alternatives

- Fire performance according to TS EN 13501-1,B1; d0 for PIR insulated cold storage panels,

- Production flexibility at any ordered length between 2 m – 12 m

- Core thickness options 75-100-120-150-180-200 mm

- According to TS EN 14509, U values range between 0,27 – 0,11 W/m2k depending on the panel thickness

- PIR insulation alternatives

Cold Room Panel Details

Family

Patron