Mobile: 8613421351153

Solar PV racking system is divided into fixed racking system and tracking racking system, which is mainly applicable to centralized and distributed power stations. Fixed racking system is divided into seasonal adjustable racking, double column racking and single column racking, which consists of column, main beam, mold bar, foundation and other components, designed according to the characteristics of the project terrain and customer requirements, with convenient installation and excellent stability.

Advantages of Solar PV Racking Systems

- Lightweight use of high-strength steel, saving materials and reducing costs.

- More than a hundred design options to adapt to various terrains and adapt to all component sizes.

- Hot-dip galvanized and aluminum-magnesium-zinc plated materials, a variety of process methods to adapt to different environmental characteristics.

Application

Pitched roofs, flat roofs, parking lots, office buildings, residential buildings, office buildings, large-scale terrestrial power plants, fishery-photovoltaic, agricultural-photovoltaic, etc.

Technical Advantages

Perfect overall program design and layout

In the overall program design, the professional technical team will fully consider the technical and economic indicators, balance the relationship between the cost and power generation gain, and combine the irradiation latitude and longitude of the region where the PV power plant is located, climate, historical extreme weather, topography, soil conditions, land costs and other complex factors, to design the appropriate technology route, product program, power plant layout, material selection and other overall program.

Advantage of Mechanical Structure Design

In the mechanical structure design link, PV power station is generally located in the outdoor, facing the wind, sand, rain, snow, air corrosion, high and low temperatures, permafrost layer and other harsh environments, PV bracket needs to meet the strength, weight wear-resistant, corrosion-resistant, anti-dumping and other high-performance standards, and must be through the wind tunnel experimental test to check its performance. Therefore, it is necessary to scientifically design the mechanical structure, reasonably select the type of material, adequately carry out testing and inspection, and effectively control the cost of the product.

Advantage of production process

In terms of production process, imported high-end automatic keel production line, stamping, cutting, laser cutting and other multi-processing techniques, which have high requirements on product processing precision, production efficiency and quality consistency.

Abundant raw material inventory

Conventional stockpile of 20,000 tons, including galvanized, aluminized zinc, zinc-aluminum-magnesium, color coated, aluminum-magnesium Yu,zinc plate, etc., with a daily output of up to 1,000 tons, which can fully meet the market demand.

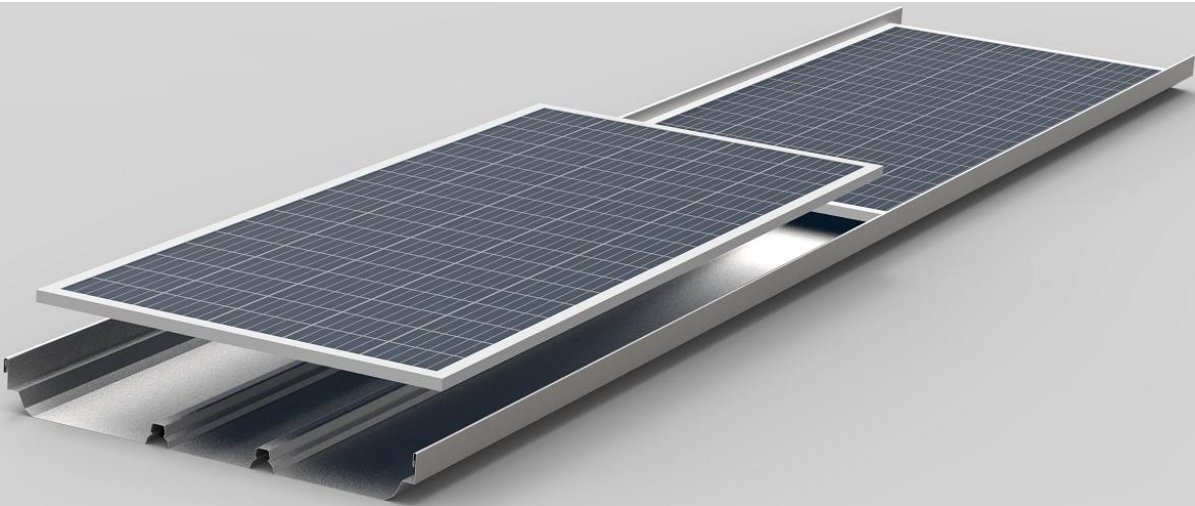

Single Column Mounting System

- Flexibility to adapt to different environments and terrains, e.g. rapid installation for agricultural and fishing projects, high degree of factory pre-installation, no need for on-site welding at the project site.

- Fully adjustable connection design according to the terrain, able to cope with the challenges of high-load project environments.

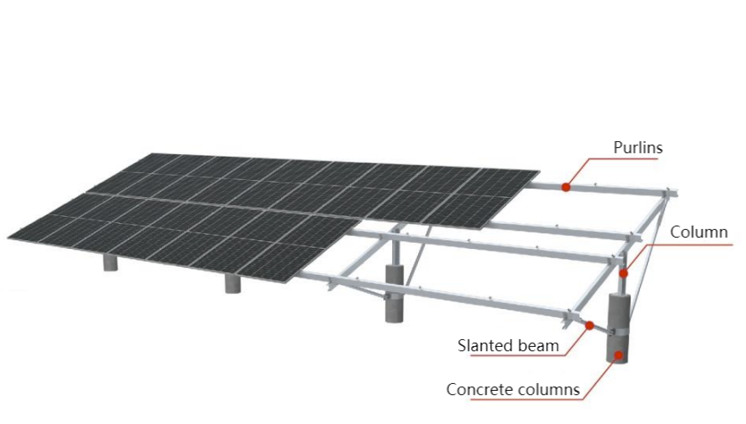

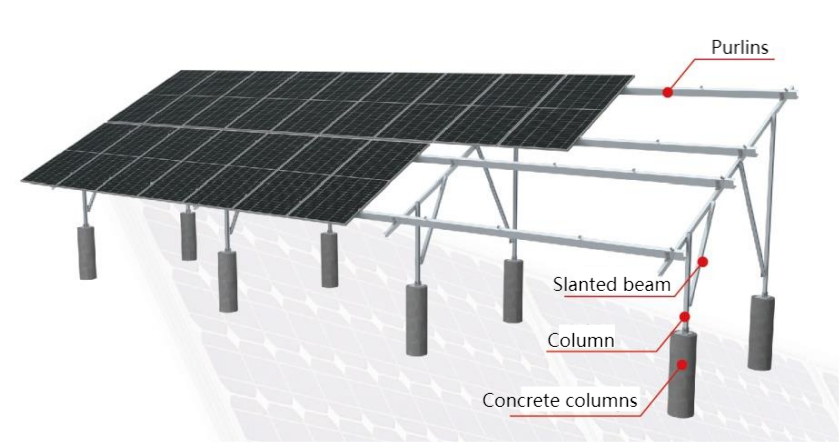

Double-column Mounting System

- Various double column solutions, can be used with different materials and foundations, good structural stability, high degree of factory pre-assembly, can be quickly installed.

- Diversified arrangement solutions, such as N-type 2 rows (4 rows) vertical (horizontal) W-type 2 rows (4 rows) vertical (horizontal), etc., which can be adapted to different power station projects:

- specially designed for harsh environments such as sandstorms, strong winds, high humidity, high temperatures, high snowfall, etc.: easy and convenient to install, reducing installation costs.