Mobile: 8613421351153

Corrugated metal sheets connection method

In modern buildings, corrugated metal sheets are widely used in roof, wall and floor systems due to their light weight, high strength, beautiful appearance and convenient construction. The correct connection design is the key to ensure its structural stability and service life. This article will introduce in detail the various connection methods of corrugated metal sheets and their design points.

Connection methods of corrugated metal sheets

Corrugated metal sheets are mainly divided into the following four types according to the connection method:

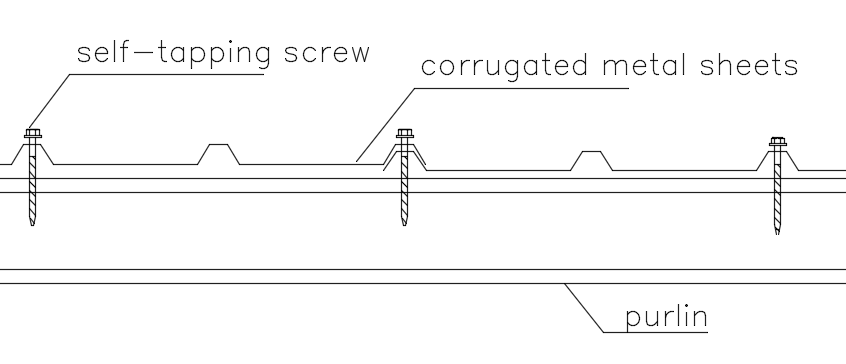

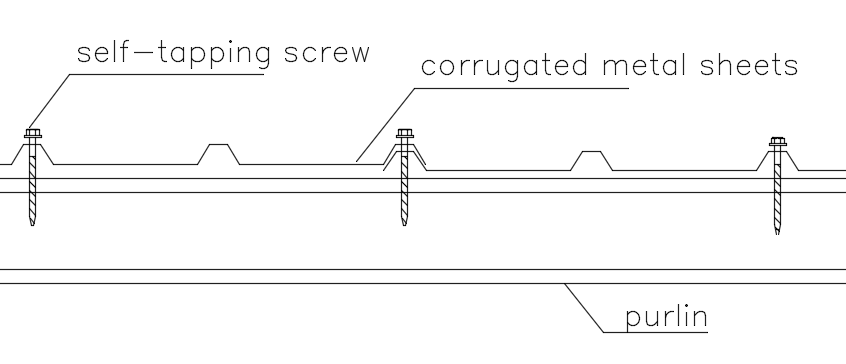

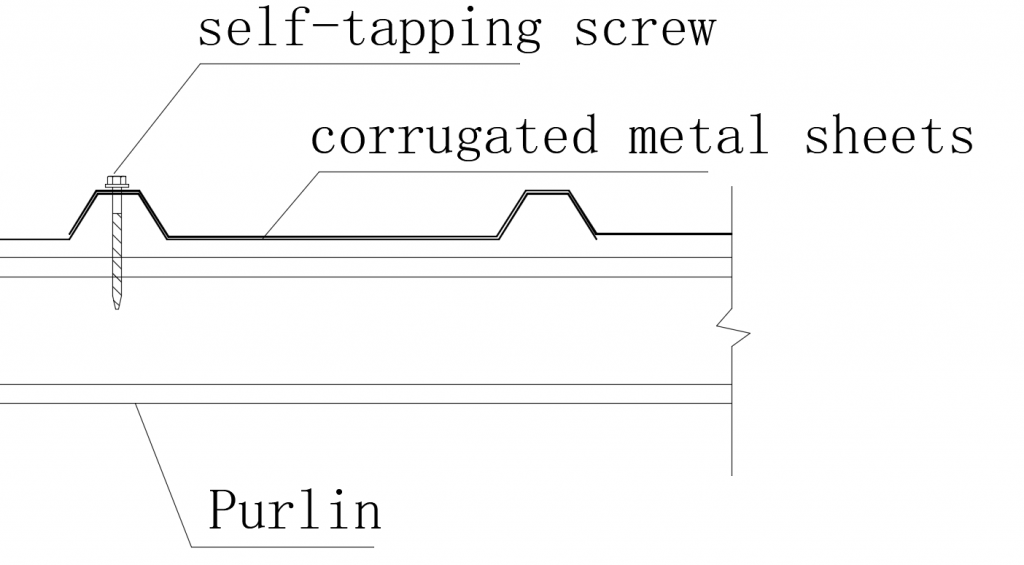

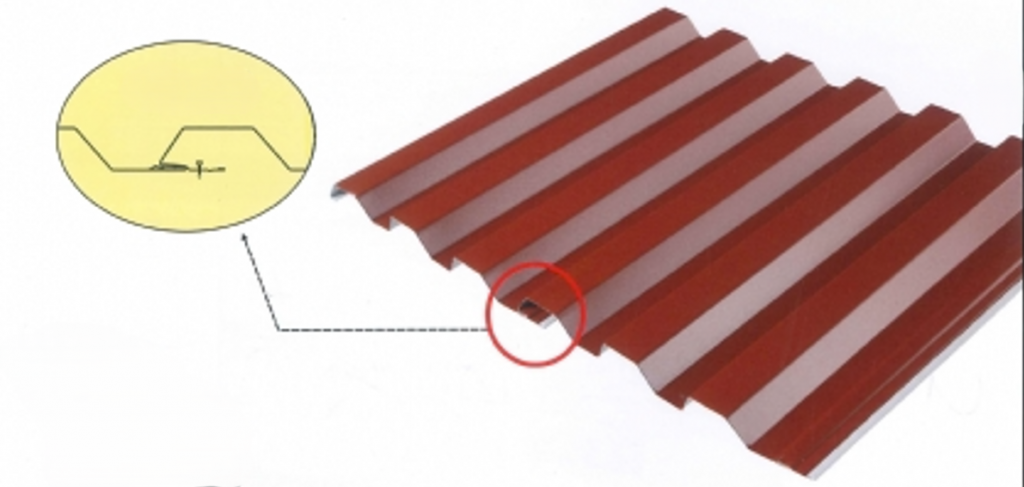

Lap connection of corrugated metal sheets

Definition: The longitudinal edges of the formed sheets can overlap each other, and the sheets are naturally overlapped and connected to the supporting structural members by fasteners.

Classification:

Roof sheets: divided into two types: without bracket and with bracket. Without bracket is suitable for low-corrugated sheets, with bracket is suitable for high-corrugated sheets. Both must ensure a minimum slope of ≥5%, and an ideal slope of ≥10%.

Wall sheets: divided into exposed nail connection and hidden connection, suitable for a variety of sheets such as steel sheets, stainless steel sheets, aluminum alloy sheets, etc.

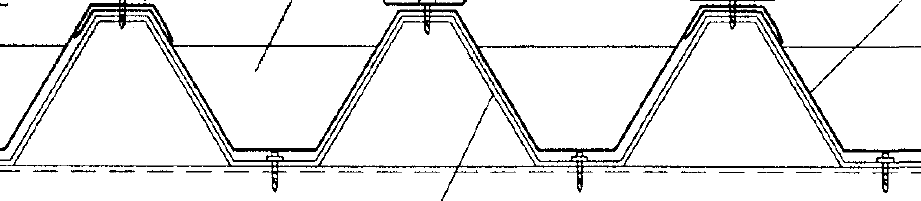

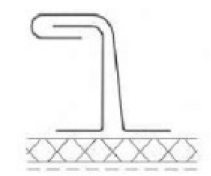

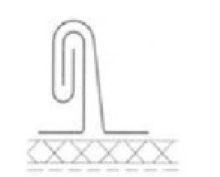

Occlusal connection of corrugated metal sheets

Definition: The longitudinal edges of the formed sheets can overlap each other. After the sheets are overlapped, they are rolled and bitten along the length direction by special machines and connected to the supporting structural members through fixed brackets.

Classification:

Roof sheets:

180° bite connection: suitable for steel plates, minimum slope ≥5%; short vertical edge single bite connection is suitable for a variety of plates, minimum slope ≥45%

270° bite connection: It is divided into fixed bracket sliding connection and fixed bracket bite connection. The former is suitable for aluminum alloy plates, and the latter is suitable for steel plates. The minimum slope is ≥5%

360° bite connection: suitable for steel plates, with a minimum slope of ≥5%; the short vertical edge double bite connection is suitable for a variety of plates, with a minimum slope of ≥5% for decorative layers and ≥45% for waterproof layers.

Wall sheets: Low standing edge single bite connection, suitable for a variety of plates, the connecting parts are made of stainless steel plate.

Snap-fit connection of corrugated metal sheets

Definition: The longitudinal edges of the formed sheets can overlap each other, the sheets are fastened together, and connected to the supporting structural members through fixed brackets.

Application: Roof sheets snap-on connection, suitable for 550MPa high-strength steel plate, minimum slope ≥5%.

Lock connection of corrugated metal sheets

Definition: The formed sheets are connected to each other at the overlapped sheets and are connected to the supporting structural members by connecting them together with the connecting parts.

Application:

Roof sheets: Flat lock connection, suitable for a variety of panels, minimum slope ≥ 45%.

Wall sheets: divided into hook connection and flat lock connection, suitable for a variety of panels.

Connection of corrugated metal sheet to main structure

Method: Directly fixed to the supporting structure member through fasteners, or indirectly fixed through brackets or connectors.

Bracket type: including fixed brackets and sliding brackets. 360° bite edge connection often uses sliding brackets for connection.

Correct connection design is crucial for the application of corrugated metal sheets. By choosing the right connection method, you can not only enhance the stability of the structure, but also extend the service life of the building.