Mobile: 8613421351153

The Solideck Clean room ceiling panel is sandwich panel made of 0.4-0.8 mm color-coated steel or stainless steel with composite insulation core materials . There are many choices of insulation core materials, such as Polystyrene, rock wool, magnesium oxide board, polyurethane, aluminum honeycomb etc.

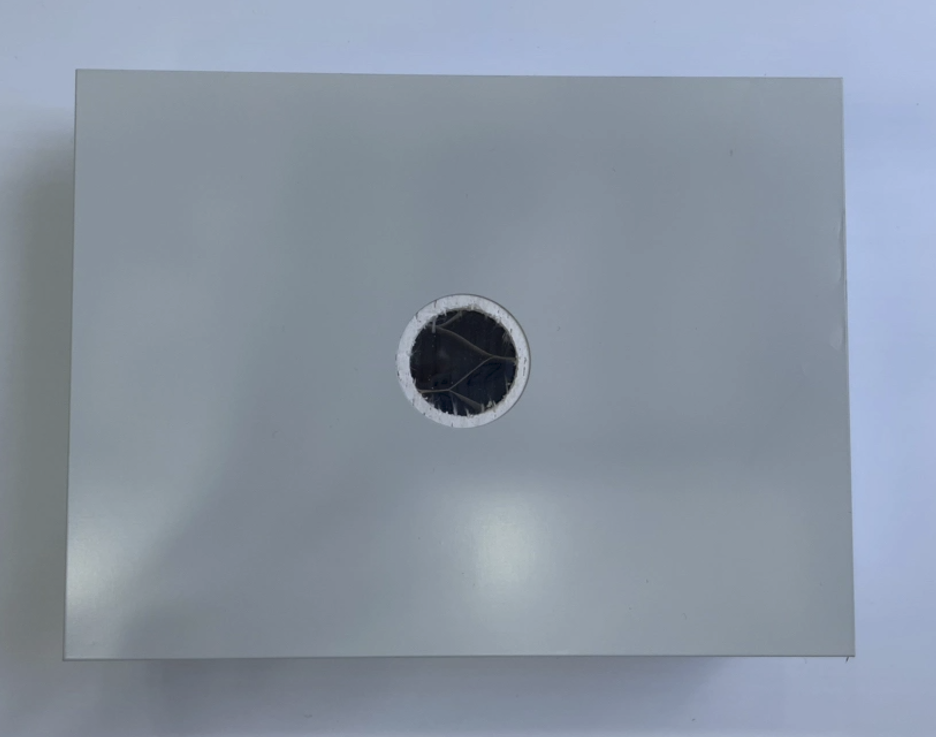

The design of the Solideck Clean room ceiling suspension system is very sturdy and resistant to deformation.There are also a large number of equipment components that can be installed on the Clean room ceiling panels. such include the fire sprinklers, smoke detectors, high-efficiency filters, FFU filters,purification LED lights, etc. You could also have a bunch of electromechanical and ventilation ducts.

A lot of construction and follow-up maintenance operations are required when working with clean room ceilings. The ceiling needs to have an impressive load bearing performance, able to withstand deformation and cracks, and have a certain degree of impact resistance.Our excellent clean room ceiling structure system will meet your requirements for setting up different clean rooms.

Types of Clean Room Ceiling Panel

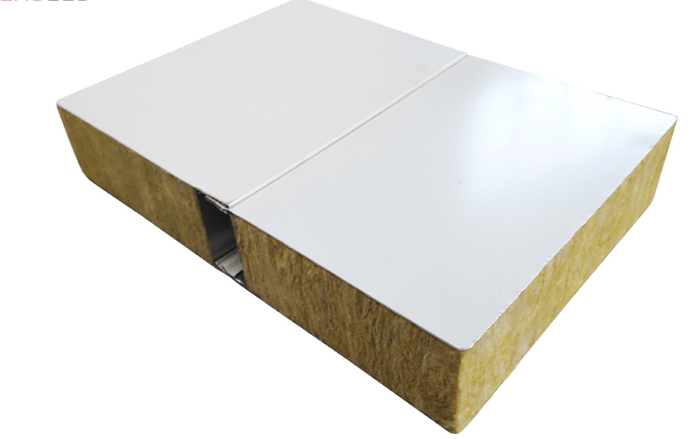

Rock Wool Clean Room Ceiling Panel

Rock wool clean room ceiling panel has good mechanical properties, high strength, impact resistance, and has the advantage of Class A flame retardant. These panels offer excellent thermal and acoustic insulation properties, which helps maintain a consistent temperature and reduce external noise in clean rooms.It is more suitable for food factories.

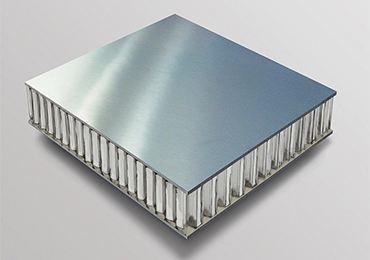

Aluminum Honeycomb Panels withstand repeated cleaning and sanitizing with various chemicals to resists microbial and fungal growth. They are non-outgassing, non-particle shedding and anti-static as well as lightweight and non-combustible. It offer acoustic, thermal, and dust resistance properties that are essential for clean rooms.

PU clean room ceilings feature low thermal conductivity, noise resistance and easy assembly. The wall coverings are made of high quality aluminum or stainless steel panels, providing plenty of strength and protection against bacterial and fungal growth for any laboratory or clean room application.

Paper Honeycomb Panel consists of a sheet of honeycomb core sandwiched between sheets of Aluminum or cured Prepreg laminates to provide an exceptionally stiff yet lightweight board. Both sides of paper honeycomb sandwich plate, surrounded only by cold-drawing-based framework, in laying out the paper honeycomb core laminated molding.

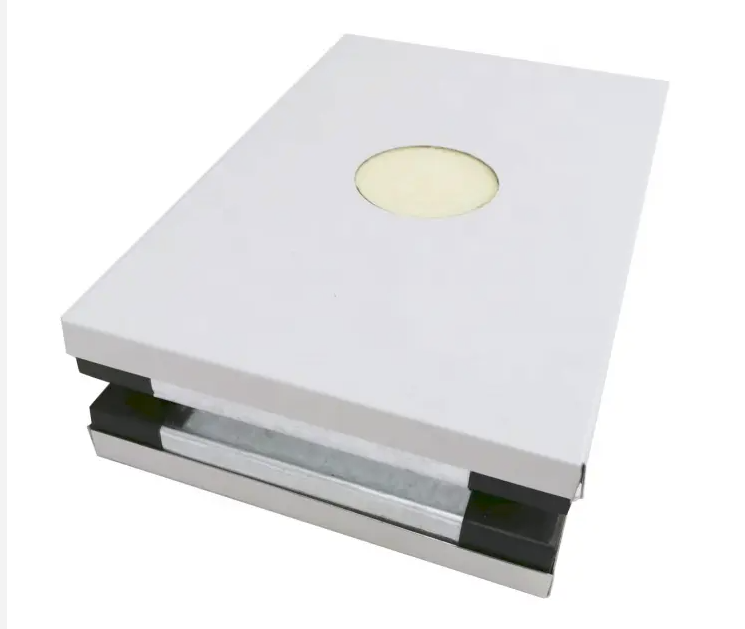

Glass magnesium hollow clean room ceiling panel

Glass magnesium hollow clean room ceiling panel is a kind of normal ceiling panel in clean room industry ,which is made of powder coated steel surface sheet, surrounded galvanized steel keel and infilled hollow glass magnesium core material.If filled with rock wool in the middle of the glass-magnesium, it will form a glass-magnesium rock wool clean room ceiling panel with better fire resistance.