Mobile: 8613421351153

PIR sandwich panel

PIR (Polyisocyanurate Foam) is a foaming material made by reacting an isocyanate with polyether after catalyst action, and its physical and fire resistance are better than ordinary polyurethane. lt is an ideal organic low-temperature insulation material with small thermal conductivity,lightweight, and shock resistance. PlR sandwich panel is widely used in thermal insulation in the construction industry.

When evaluating insulation materials, we need to consider the overall performance and long term benefits of the envelope, and there is no doubt that PIR sandwich panel is the best solution for you. PIR sandwich panel is the most cost-effective insulation that is energy efficient and ensures longevity of the roof and walls.

Advantages Of PIR Sandwich Panels

PIR Sandwich Panels offer four key benefits: Insulation Properties, Fire Resistance, Lightweight, Strength & Durability.

Insulation Properties

The main advantages of PIR sandwich panel is the high level of thermal insulation. PIR foam has a closed cell structure with a closure rate of more than 90%, , which means that it significantly reduces heat transfer, keeping the interior of the building warmer in winter and cooler in summer. The rigid core polyurethane foam of PIR sandwich panels is generally composed of polyester polyol and high isocyanate. This composition results in low thermal conductivity and a high R-value, with a thermal conductivity of 0.021 (w/m.k) for PIR sandwich panels, making it an effective barrier against heat transfer.

Fire Resistance

A advantage of PIR sandwich panels is their fire-resistant properties. PIR is the use of polyester polyols instead of polyether polyols used in PU, and isocyanate reaction to generate. During the period of excess isocyanate spontaneous reaction to generate a six-membered ring molecular structure, which can promote the combustion of coking into charcoal, to enhance the fire-resistant properties of the panel. These advantages make it the preferred choice for a wide range of buildings. It also have low smoke emissions, ensuring that in the event of a fire, smoke will not hinder evacuation efforts.

Lightweight

Another advantage of PIR sandwich panels is their light weight; with a density of 60 to 80 kg/m3, PIR foam is one of the lightest insulation materials on the market. This characteristic makes PIR sandwich panels easy to handle and install, requiring lower labor costs and minimal mechanical equipment. The lightweight nature of sandwich panels allows them to be used in a wide range of applications, including clean room ceiling panels and clean room partitions, in addition to building facades and roofs. Since PIR sandwich panels reduce the overall weight of the building, this is a major advantage in earthquake areas.

Strength & Durability

PIR sandwich panels have excellent structural properties, making them suitable for building walls, roofs, and floors. PIR sandwich panels have 250-300 kPa, have a higher compressive strength , meaning that they can withstand higher loads and pressures without being deformed. This higher compressive strength of PIR panels makes them a suitable choice for buildings that require structural support, such as cold storage facilities and industrial buildings. PIR panels can also be used as roof panels in areas with heavy snow loads, as they can withstand the weight without deforming.Good durability due to the properties of the core material.

Classification of PIR sandwich panel

PIR sandwich panels are divided into four categories based on their function: PIR Roof sandwich panel, PIR wall sandwich panel, cold room panel .

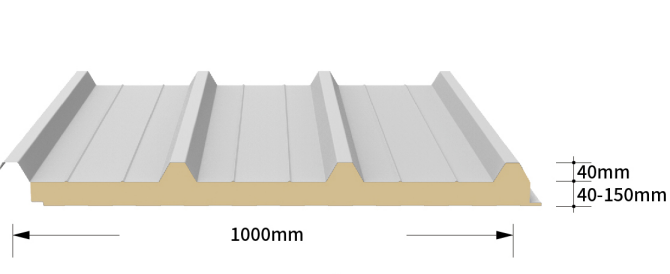

The roof sandwich panels with a polyisocyanurate PIR core (trapezoidal profiled external surface) are used for various types of roofs with small to medium inclinations. Thanks to the proper profiling of the locks, the SDpanel PIR roof sandwich panels have total tightness to air, steam and rain infiltration. Roof panels are used as a material for the roofs of production, store, logistics or industrial buildings.

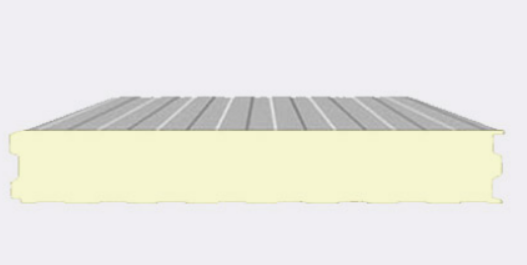

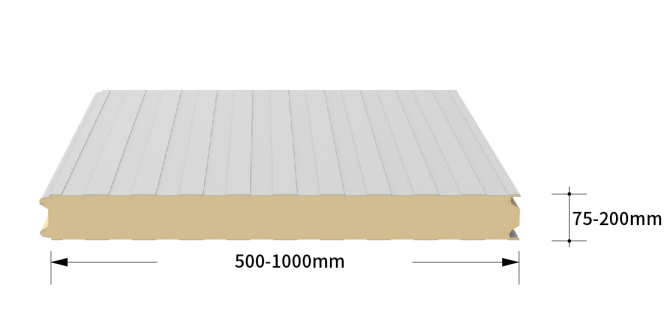

The wall sandwich panels with a PIR polyisocyanurate core in steel cladding are currently the most popular building material used for external wall cladding when constructing enclosed, industrial, warehouse or logistics buildings. The SDpanel PIR wall sandwich panels are also used to create partition walls, suspended ceilings and partitions in a variety of buildings. They are characterized by very good thermal and acoustic insulation.

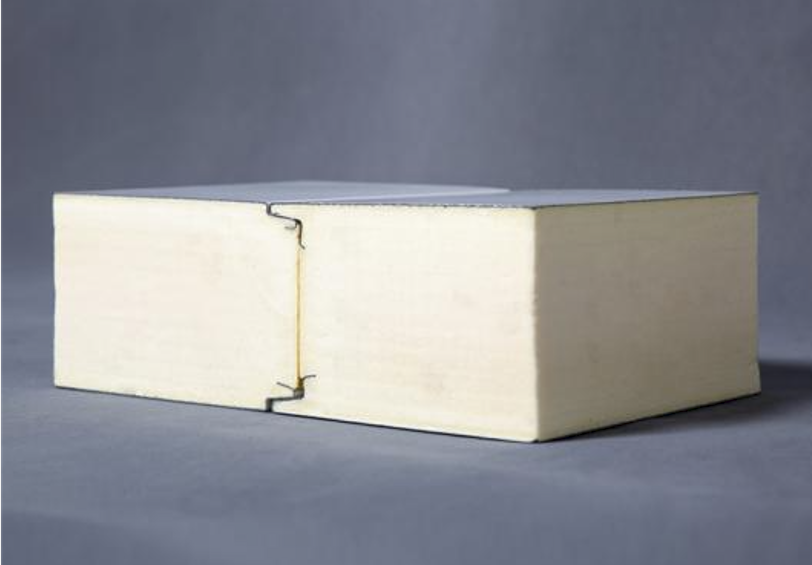

The SDpanel PIR cold room panels are used primarily for the construction of cold stores and freezer rooms, as well as external and internal walls in enclosed buildings, industrial buildings, warehousing or production buildings, and agricultural and food processing buildings.

PIR clean room panel is designed for use in temperature controlled and hygienically safe environments such as food processing facilities, frozen food, pharmaceuticals, refrigerated/frozen warehouses and clean rooms due to their thermal, acoustic, flame retardant and anti-bacterial properties.