Mobile: 8613421351153

What Is Metal Roofing Panels

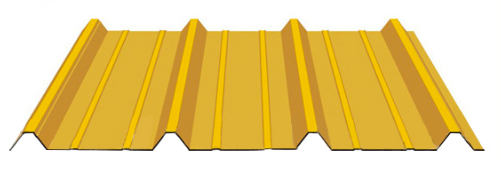

Metal roofs are made from a wide range of materials including everything from steel to aluminum, copper, zinc, alloys, and even stainless steel. These materials come in several styles and sizes which makes them perfect for most any application, from low-slope roofs to high-pitch roofs, from pitched roofs to flat roofs. Metal roofing usually comes in sheets, which can be further divided into two sub-categories: flat and standing seam metal roofs.

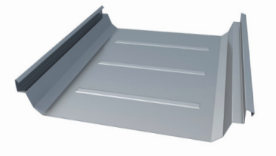

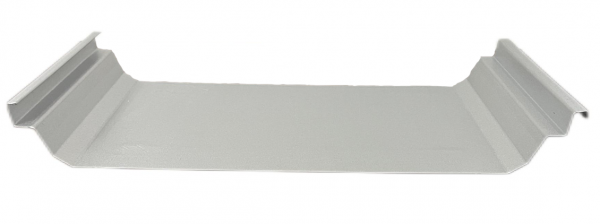

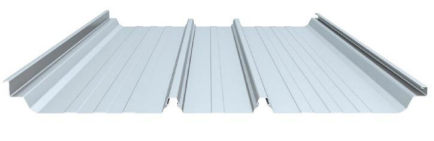

Standing seam metal roofs are typically composed of thicker material than that used in flat metal roof systems. They are installed with either a series of clips or screws, depending on the type of material. Standing seam metal roofs usually have a ribbed texture or a more intricate, wavy finish.

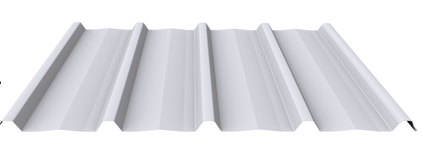

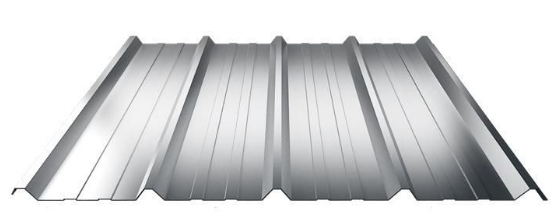

Flat metal roofing panels are the most common type. They are typically made of lightweight, corrosion-resistant material, such as aluminum, steel, zinc, and other alloy materials. The panels generally come in sheets and feature a sleek, smooth finish that provides excellent protection against water and sunlight. Flat roofing panel systems commonly used in residential and commercial buildings.

What Are the Benefits of Metal Roofing panels

Metal roofing offers a fairly long list of benefits. When compared to traditional single roofs, they are hands-down more durable. Metal roofs can last up to 50 or 60 years, while a shingle roof will need to be replaced in about half of that time. And when it is time to replace them, the metal panels are recyclable, which contributes less material to landfills.

Metal roofs are customizable in a wide selection of colors and materials range from minimalistic and cost-effective to sleek and modern. As the residential sector has adopted metal roofing for environmental reasons, newer decorative styles are becoming available as well.

Metal roofs are also more sustainable in other ways. As the cost of utilities continues to rise and we all try a little harder to lessen our impact on the environment, energy-efficient building materials become much more important. Depending on the region and personal habits, a metal roof on a residential home can decrease energy bills by up to 40%. Reflective metal roofing can reduce air temperatures in a building by an average of 12 degrees, lowering cooling costs.

Durability

Longevity

Metal roofs are known for their durability and long life span. Metal roofs are able to withstand winds of up 120 miles per hour, as well as extreme temperatures ranging from -50 degrees Fahrenheit to 150 degrees Fahrenheit. Metal roofing panels are not a major component of a fire and won’t spread it , are also often manufactured to be Class A fire-rated and non-combustible. They also are more resistant to punctures and hails storms than other roof materials, like shingles, which can be torn or damaged in a hail storm.

Metal roofing is made to last longer than any other roofing material on the market. Many consumers decide to choose metal panels because, depending on the substrate material, metal roofing can go 60 or more years without signs of corrosion or degradation. while shingles usually need to be replaced in 15-20 years.

Eco-Friendly

Aesthetics

Metal roofs are 100% recyclable, which makes them a great choice for anyone looking for an eco-friendly roofing material. Most metal roofs are made of aluminum or steel, which can both be recycled when it is time for a new roof.

Metal roofs offer a great way to enhance the look of your home. These roofs are available in a variety of colors and styles to suit any home and public building. For home use, you can choose to install metal roofs that resemble shingles, making it hard to tell that is it’s actually metal. When used in public buildings and factory buildings, there are more wonderful shapes for designers and homeowners to choose from.

Metal Roofing Panel

What is Metal Siding Panels

Metal siding panel provides a popular, durable alternative to vinyl or wood. Generally, metal siding is made from steel or aluminum, both of which are fire-resistant and low maintenance.This type of siding dates back to the 1940s, but it really started to grow in popularity in the 1980s. It provides a more sophisticated and glossier look than wood or simulated wood.

What Are the Benefits of Metal Siding

Metal siding provides many great benefits, whether you’re evaluating it for your home or a commercial building. Here’s a look at what some of those benefits are so you can make an informed decision about how to side your building.

Eco-Friendly

As far as siding materials go, metal siding is among the most eco-friendly options on the market.There are two big reasons that this siding is so eco-friendly.

First, it’s because you can use recycled steel to manufacture the siding and then the siding can be recycled when it’s no longer needed. Secondly, manufacturers don’t need to use any harmful chemicals,which means the manufacturing process does not leach pollution into the air.

Because it’s so low maintenance, you also won’t need to repaint or stain it like some other siding types, which is also better for the environment.

Durability Value

You’ll get great value out of steel siding. Your upfront costs will be higher, but thanks to a long and durable lifetime, the per-year expense of this siding is outstanding.

With such great durability, it also isn’t susceptible to insect and wildlife damage. This strong material stands up well to storms and tough conditions. Abrupt temperature changes won’t negatively impact the materials.

Excellent Soundproofing

Metal siding is thicker than other types of siding, which makes it more soundproof. Additionally,your siding contractor can insulate your siding easily to make it more temperature resistant too. Urban areas are a great place to use steel siding to reduce the noise from busy roadways and foot traffic.

Metal Siding Panels

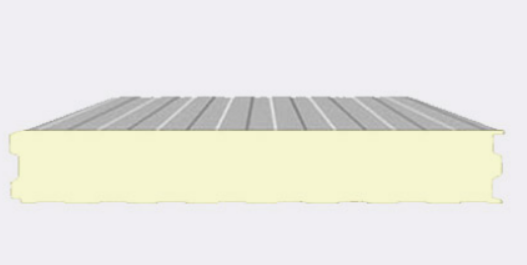

Sandwich panel

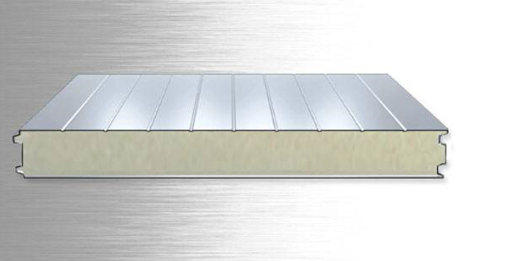

What are the sandwich panels

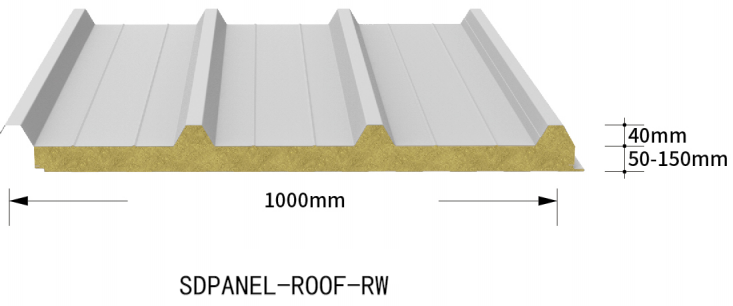

Sandwich panels, also known as composite panels or structural insulated panels, are a type of multi-layer structural cladding system that consists of two thin and strong metal sheets attached to a substantiating core material. The metal sheets are coated with a corrosion-resistant coating and the core material is usually polystyrene, polyurethane, mineral wool.

The structural functionality of a sandwich panel is similar to the classic I-beam, where two face sheets primarily resist the in-plane and lateral bending loads (similar to flanges of an I- beam), while the core material mainly resists the shear loads (similar to the web of an I-beam).[1] The idea is to use a light/soft but thick layer for the core and strong but thin layers for face sheets. This results in increasing the overall thickness of the panel, which often improves the structural attributes, like bending stiffness, and maintain or even reduce the weight.

In building and construction, these prefabricated products designed for use as building envelopes. They appear in industrial and office buildings, in clean and cold rooms and also in private houses, whether renovation or new-build. They combine a high-quality product with high flexibility regarding design. They generally have a good energy-efficiency and sustainability.

What are the advantages of sandwich panels

Sandwich panels are an increasingly popular building material that offer a number of advantages. These panels are constructed from two pieces of metal, a top layer and a bottom layer, that are connected together with an insulating core of foam or other material. Using sandwich panels for construction makes the structure stronger, more energy efficient, and provides better acoustic and thermal insulation than traditional building materials like wood and concrete.

Insulation

Sandwich panels made with core polyurethane, poly-isocyanurate foam or mineral wool Their insulation has excellent thermal insulation performance, which could be proved by comparing with other construction materials in heat transfer coefficient. The panel has high insulation properties as much as 14-80 times than brick and concrete. The panel therefore is a best choice for the use of strict control of temperature requirements.

Prevent condensation

There are two methods for building thermal insulation in general: internal thermal insulation and external thermal insulation. For internal insulation it would generate temperature difference in different divided spaces, such as indoor area and the back of small rooms, and resulting condensation normally. On the other hand, external insulation covers a building completely with insulation material; therefore the divided space between indoor area and the back of small rooms sharing stable temperature will not generate condensation. Sandwich panels adopt external insulation method which would prevent condensation effectively.

Fire Resistance

The use of fire-resistant or fire-retardant materials for the core material in the middle of the sandwich panel can stop the fire from spreading in the event of a fire. The outer “skins” of the panel are designed to resist the spread of flames. These skins are often treated with special fire-resistant materials that create a barrier between the flame and the interior of the panel. This improves fire safety and reduces the rate at which fire can spread.

Durability

Sandwich panels boast excellent strength and durability. The core is made from either Styrofoam or polyurethane foam. This foam insulation is both lightweight and incredibly strong, making it extremely capable of withstanding considerable force. It can also absorb shock, while retaining its structural integrity over extended periods of time.The prefabricated panels are made from either steel or aluminum, giving them an even greater strength. This makes sandwich panels an ideal choice for applications such as walls and roofs.

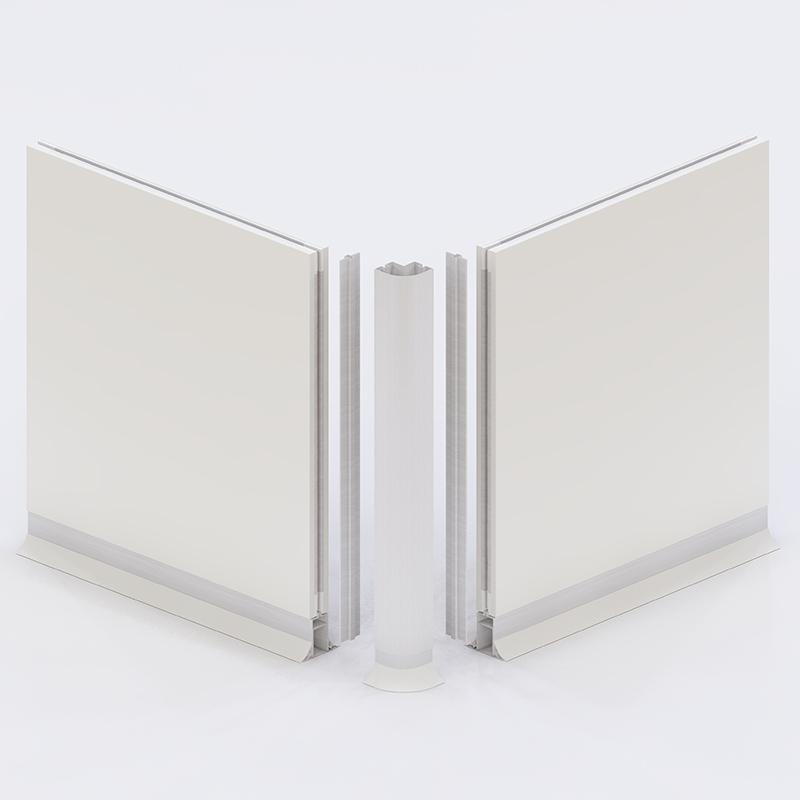

Classification of sandwich panel

The sandwich panels are classified according to the part of the sandwich panel, sandwich panels are divided into roof sandwich panels and wall sandwich panels.

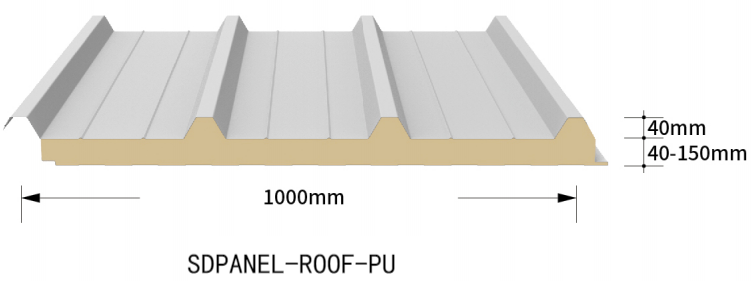

Roof sandwich panels

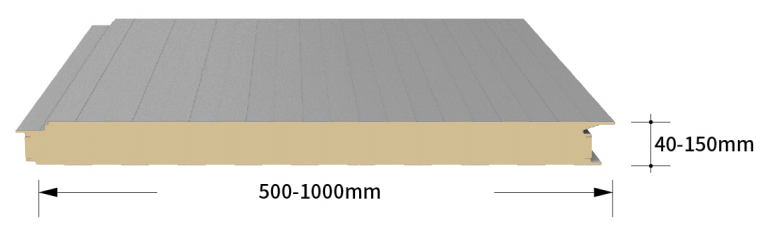

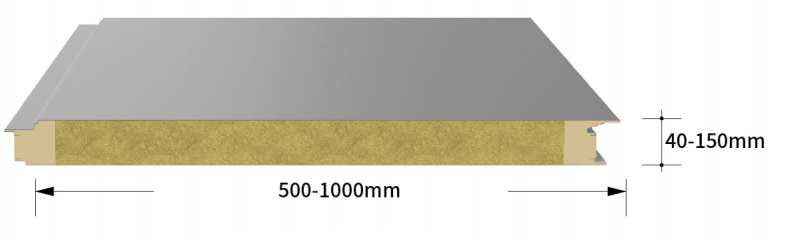

Wall sandwich panels

Cold Room Panel

Clean Room Panel System

Photovoltaic roof panels

In the context of the global energy shortage, the use of solar energy is very much in demand, and Solideck, which has been specializing in metal enclosure systems for nearly two decades, is following the trend by developing photovoltaic energy for the building envelope. From BIPV to BAPV and Solar PV Racking System, Solideck’s photovoltaic roof panels will be seen in the buildings of the future as a result of the close integration of building and photovoltaic.

LP-BIPV ROOF PANELS

LP BIPV ROOF PANEL is Solideck’s self-developed SLP1063,SLP700 which is specially designed for photovoltaic roof integration. This photovoltaic roof panels takes into account the size and installation of photovoltaic panels, and maintains the corrosion and seepage resistance of roof panels, as well as guaranteeing the aesthetics of the roof.

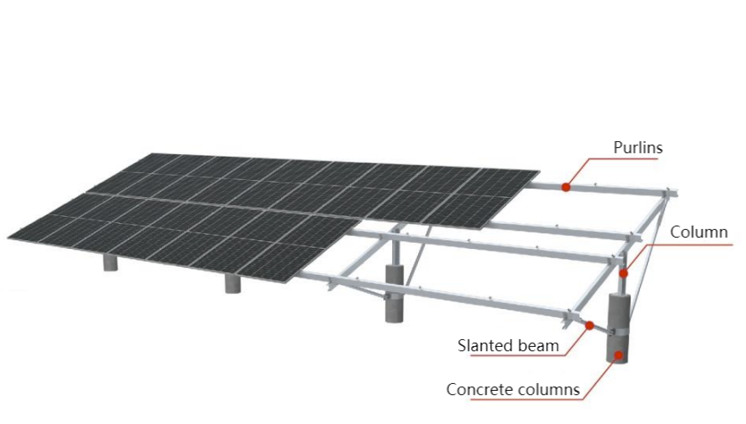

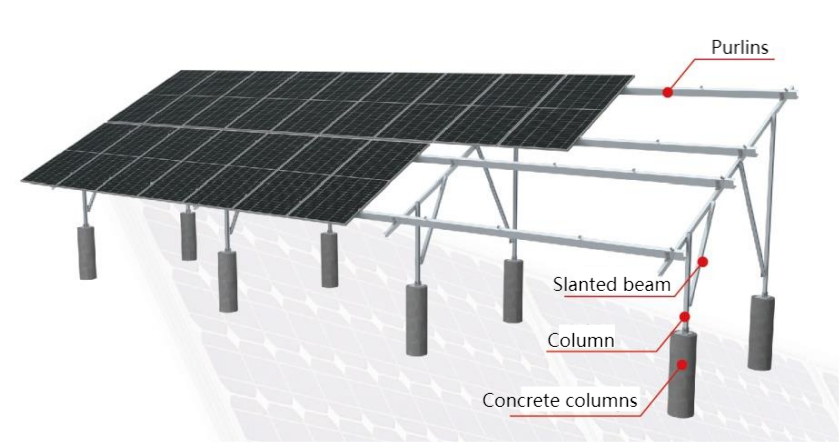

Solar PV Racking System

Solar PV racking system is divided into fixed racking system and tracking racking system, which is mainly applicable to centralized and distributed power stations. Fixed racking system is divided into seasonal adjustable racking, double column racking and single column racking, which consists of column, main beam, mold bar, foundation and other components, designed according to the characteristics of the project terrain and customer requirements, with convenient installation and excellent stability.

Quality. Specialty. Performance.

Established in 2006,The Solideck. As one of the manufacturing bases,Solideck has become a famous brand and the first choise for building system in China.

Solideck has always been in the leading place of steel building system , mainly including advanced prefabricated floor deck systems and roof(wall) cladding systems. Over the years, the company has developed a variety of Metal Roofing And Siding Panels types in combination with market demand , and has done a lot of work in the use of related technologies.

Solideck has a 5000 ㎡ workshop with a strong technical team with 10 engineers. Since establish, Solideck has done more than 100 projects, including super high-rise buildings, factories, hospitals, cultural facilities, and transportation facilities, etc.We have accumulated valuable experience in this industry, which is also the reason that many customers choose us.

We have a successful track record. We ensure that all projects are executed with the utmost professionalism using quality materials, while providing the support and accessibility you need. We can deliver goods within a week for those we have materials in stock. Solideck is in Shanghai, the economic.