Mobile: 8613421351153

PIR sandwich panels revealed (2)

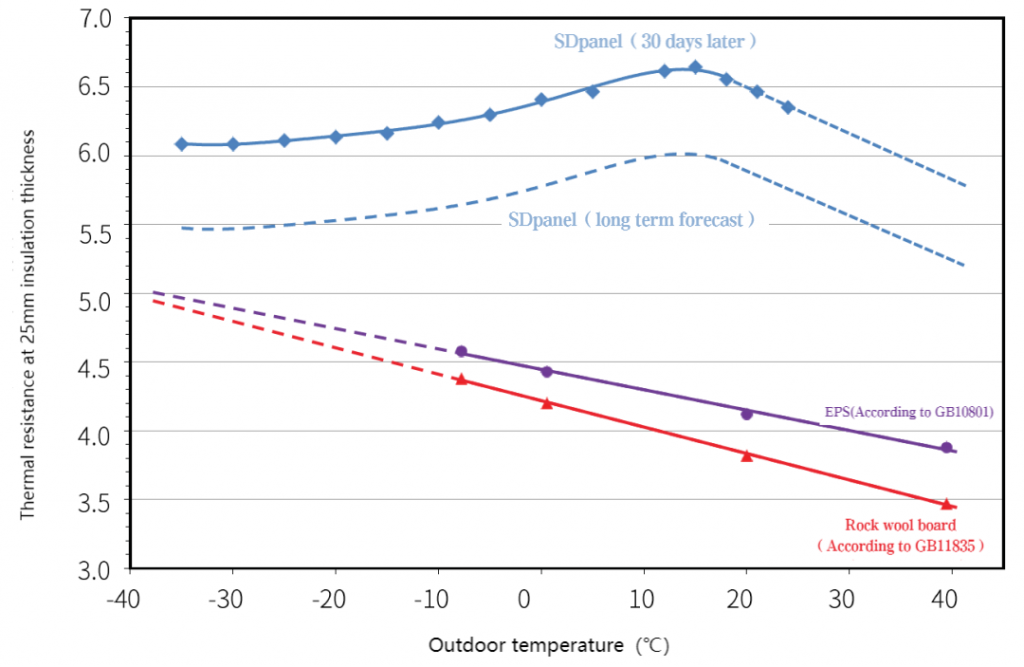

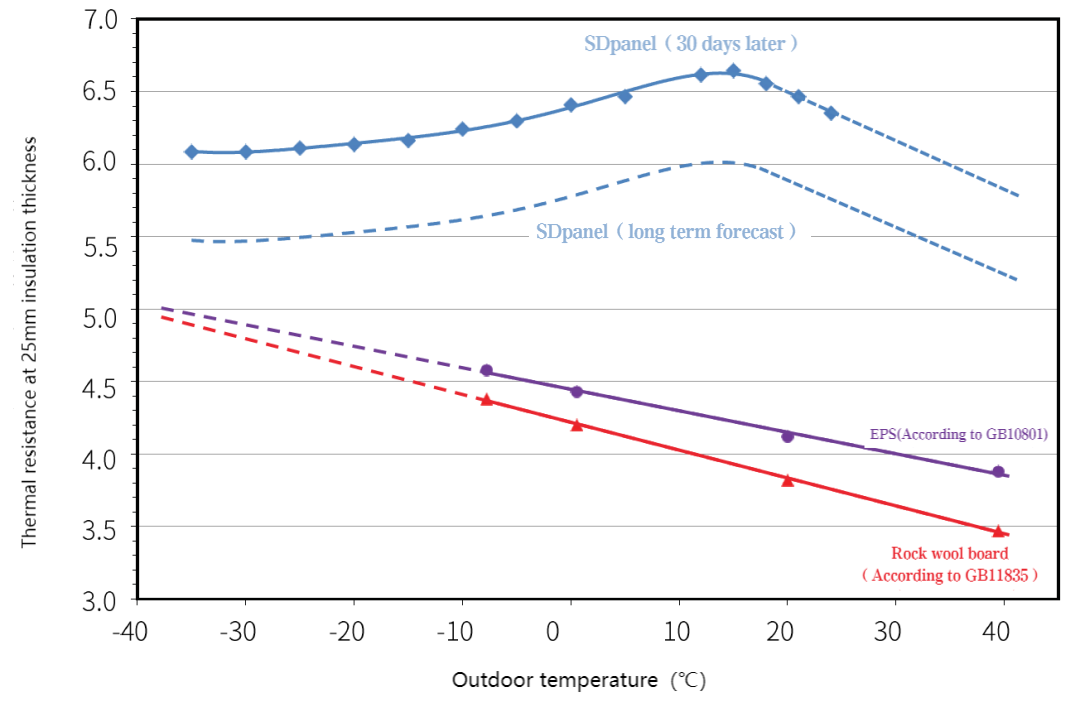

In the last article, SDPanel compared the thermal performance of PIR sandwich panels with EPS sandwich panels and rock wool sandwich panels, and we found that PIR sandwich panels have a higher thermal resistance value, which is more capable of improving energy efficiency and reducing energy consumption. And after that, we PIR sandwich panels other characteristics.

Effective roof weight

Roof insulation system is an important component of the constant load of the roofing system, building structure design, reduce the weight of the roof itself, can save the amount of structural components and the corresponding construction investment. According to the “Code” requirements, the use of PIR sandwich panels, XPS sandwich panels and other combustible thermal insulation materials, must be added 10mm fire boards, so there will be a misunderstanding that the PIR thermal insulation roof system will be heavier than the use of non-combustible thermal insulation materials. Is this really the case? Let’s do some calculations before jumping to conclusions.

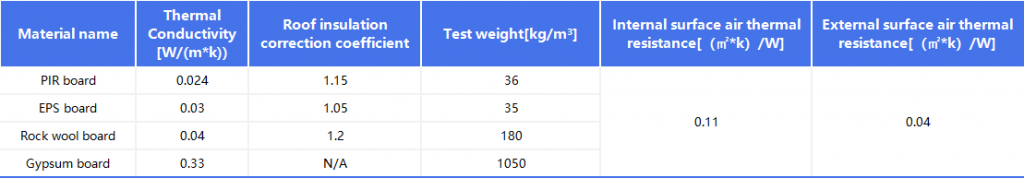

In accordance with the “unified standard for energy-saving design of industrial buildings” in different climatic regions, different body shape coefficients of industrial building plant requirements of the roof heat transfer coefficient of the maximum limit requirements for the design basis, according to the mechanism of heat transfer, respectively, the use of PIR sandwich panels + gypsum boards, XPS sandwich panels + gypsum boards and rock wool boards under the three types of heat preservation program, the minimum thickness of insulation required, as well as the self-weight of the roof insulation system.

The calculation results show that among the three insulation schemes, when the energy saving requirement is higher and the required insulation thickness is thicker, the difference in the self-weight of the roof under the three insulation schemes is greater. Among them, the lightest is the insulated roof of PIR board + 10mm gypsum board. When the roof heat transfer coefficient is required to be ≤0.45 W/(m2∙K)], the self-weight of the roof insulated with rock wool board is 42% higher than that of the insulated roof with PIR board, which is already close to half.

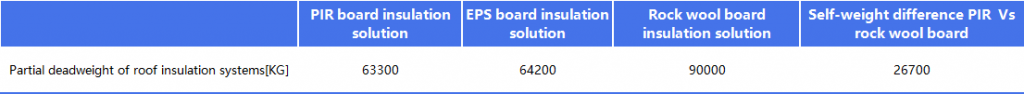

Suppose, there is a building project in Thunder Bay with a roof area of 5,000 square meters, the building form factor is greater than 0.15, the roof heat transfer coefficient needs to be ≤ 0.45 W/(m2∙K) according to the requirements of the “Unified Standard for Energy Saving Design of Industrial Buildings”, and the self-weight of the roof using the three options are:

The project example above shows that the difference in the dead weight of the roof between a rock wool board insulation solution and a PIR board insulation solution is 26,700 kg. This shows that the difference in the choice of insulation material leads to a difference in the dead weight of the roof, and a difference in the structural design of the roof in terms of the constant loading of the roof. In order to ensure safety, the designer must design more structural supports or use stronger steel, which means more construction costs. This incremental cost increases as the roof becomes more energy-efficient and the roof area becomes larger.

Therefore, PIR is also the most economical insulation solution from the point of view of reducing the structural cost of the roof.

Compressive strength

The compression strength of the insulation board is an important mechanical performance evaluation index of the roof insulation system second only to the thermal performance. The compression strength of the insulation material required by the code is the maximum pressure that the insulation material can withstand when 10% deformation occurs.

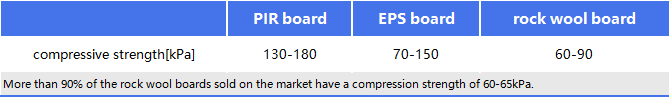

The following chart lists the compression strength range of PIR board, EPS board and rock wool board commonly used for roof insulation.

Higher compressive strength means that the insulation can withstand stronger roof loads (constant and live). Roof loads include pedestrians, walkway slabs, standing water, etc.

The compression strength of PIR boards is up to 130kPa, which is fully capable of withstanding high strength roof loads, and its compression strength does not affect the bulk density or thermal parameters. The compressive strength of rock wool products is mainly improved by increasing the capacity, the higher the capacity, the thermal conductivity and roof weight will become larger, that is, energy saving and cost must be sacrificed in exchange for high strength.