Mobile: 8613421351153

Characteristics of Mechanical Clean Room Panels

Common clean room are mainly divided into handmade clean room panels and machine-made panels according to their production methods. We introduce the classification and characteristics of mechanical clean room panels.

Classification of mechanical clean room panels

According to the difference between the core material and the surface layer, the clean room panel is divided into the following four types.

Mechanism rock wool sandwich panel

A. Composition: color steel plate + filled rock wool inside + color steel plate, ≥ 80kg/m3

B. Process: through the high-speed continuous automated forming machine heating, pressure composite, after trimming, grooving and become.

C. Characteristics: the product has a smooth and flat surface, beautiful, insulation, heat preservation, seismic, fire performance (≥ 90 minutes) in line with international standards. Construction and installation are convenient and quick.

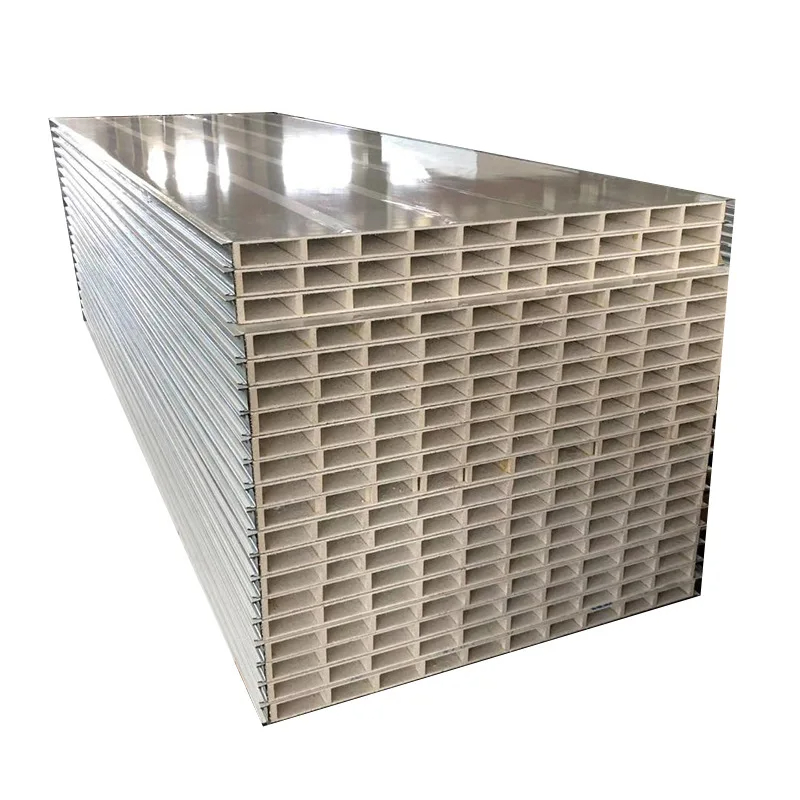

Mechanism magnesium sulphide sandwich panel

A. Composition: color steel plate + magnesium sulphate + color steel plate

B. Process: core material capacity of 220-280kg/m³, using magnesium sulfate, magnesium oxide, polyphenylene particles, chemical additives and other production and become, compressive strength of up to 60 MPa, flexural strength of up to 9 MPa.

C. Characteristics: magnesium sulfate plate has good fireproof performance, is a non-combustible plate, the flame duration of combustion time is zero, 1200°C no fire, to achieve the fireproof non-combustible level A1, waterproof and moisture-proof, gas hardness, resistance to bending and compression, bearing capacity, bearing capacity>1000N/㎡. Suitable for clean room ceiling.

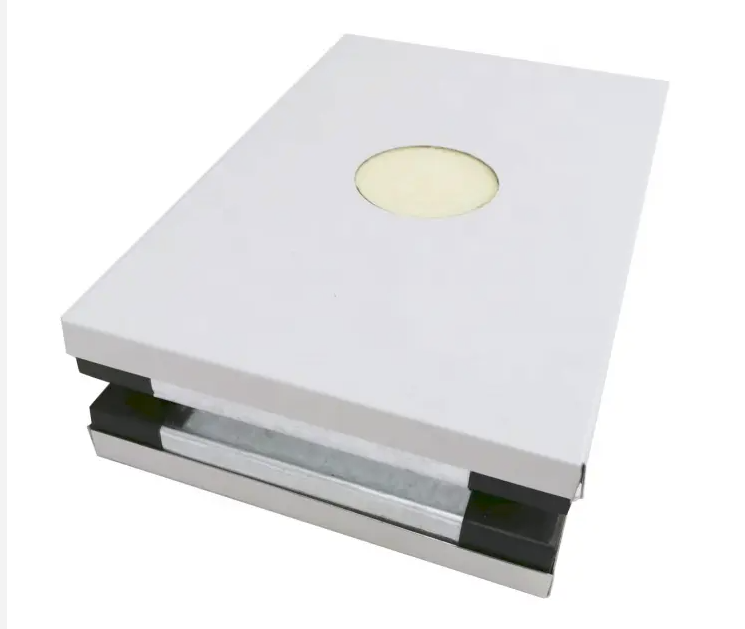

Mechanism hollow glass-magnesium panel

A. Composition: color steel plate + magnesium glass core + color steel plate

B. Process: magnesium glass board to magnesium sulfate as the main raw material, modified by configuration processing and made of stable performance is not easy to anti-halogen phenomenon.

C. Characteristics: hollow magnesium glass plate double-sided coating / fluorocarbon / aluminium zinc / anti-static / steel plate thickness 0.18-1.2 mm. with fireproof, waterproof, odourless, non-toxic, non-freezing, non-corrosive, non-cracking, non-deformation, non-combustible, high-strength, high hardness and other characteristics.

Mechanism silica rock purification panel

A. Composition: color steel plate + silica rock core material + color steel plate

B. Process: Silica rock core material is sandwiched inside and made of polystyrene. Silica rock board has certain elasticity and good compatibility with silicon polystyrene board and surface material.

C. Characteristics: the product has high compression resistance, low water absorption, moisture-proof, impermeable, lightweight, corrosion-resistant, ageing-resistant, low thermal conductivity and other excellent performance of the thermal insulation material.