Mobile: 8613421351153

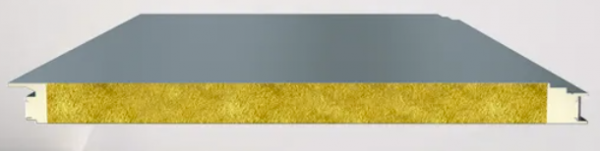

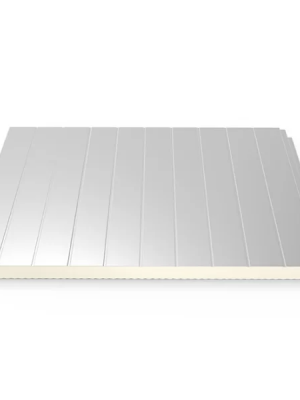

PU edge rock wool sandwich panel

Brand Name: SDpanel

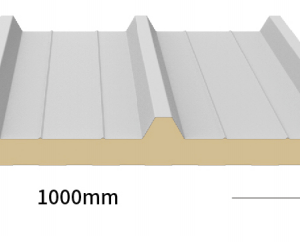

Style: PUR edge sandwich panel

Length: ≤11800 mm

Width : 1000 mm

Panel Thickness:5 0 mm/75 mm/100 mm/150 mm/200 mm

Core Materials: Rock Wool /PUR

Outer Plate Material: PPGI PE/PVDF/HDP

External skin thickness: 0.4 mm–0.5 mm

Inner skin thickness: 0.4 mm–0.5 mm

MOQ: 500 units

Delivery Time :30 days

PU edge sandwich panel is a kind of building material with good comprehensive properties, which is widely used in building insulation, sound insulation, fire prevention and other fields. It uses polyurethane as the edge sealing material and rock wool as the core material. The properties of polyurethane and rock wool are fully utilized.

Introduction of PU rock wool edge sandwich panel

Polyurethane edged rock wool Sandwich Panel is a non-combustible structural rock wool as the core material, galvanized or aluminium-zinc-coated color-coated steel sheet as the finish, polyurethane edging at both ends, and through the professionally developed adhesive, the two form an interactive composite of high-quality, energy-saving building panels.

Advantages of PU edge rock wool sandwich panel

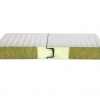

Sealing performance

Polyurethane double side seal rock wool sandwich panel adopts the assembly line production process, thus using the excellent waterproof polyurethane products to overcome the shortcomings of rock wool easy to absorb water and moisture decomposition, in physical properties effectively extend the service life of the product.

Excellent fire protection

The raw materials, production process and formula used in the polyurethane double-sided sealing rock wool sandwich panel make it have good fire resistance. Test surface shows that it has fire resistance exceeding 1000℃. The polyurethane double-sided sealed rock wool sandwich panel has passed the test of GIOROANO S.P.A, an authoritative Italian testing agency.

Good thermal insulation

The thermal insulation of polyurethane double-side-sealed rock wool sandwich panels is based on the thermal conductivity of rock wool λ = 0.043W/M²K, calculated by the thickness of the corresponding proportion of rock wool core material.

Highly effective sound insulation and absorption

Polyurethane double-sided sealed rock wool sandwich panels have a significant attenuation effect on noise transmission and are especially suitable for places where designated flights pass. In addition, after using rock wool roof panels, the indoor sound caused by the impact of rain and hail on the building’s roof steel panels is also significantly reduced.

Details of PU edge rock wool sandwich panel

Cases of PU edge rock wool sandwich panel

Packing of PU edge rock wool sandwich panel

Delivery of PU edge rock wool sandwich panel

Reviews

There are no reviews yet.