Mobile: 8613421351153

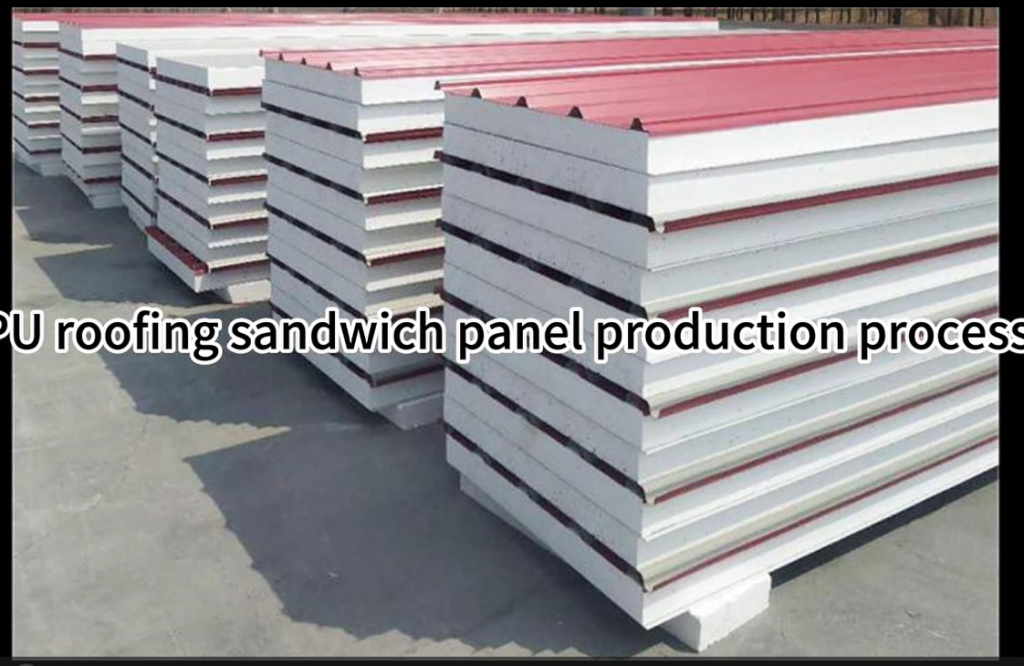

PU roofing sandwich panel production process

PU sandwich roof panel is made of color coated steel sheet as the surface material and polyurethane PU as the core material, which is heated and pressurized with glue in the continuous molding machine.

It is mainly divided into four parts of equipment composed of steel roof sheet pressure plate machine, polyurethane PU core material conveyor, and color coated flat plate conveyor, sandwich plate composite equipment.

Firstly, the production of steel roofing panels starts, the red color steel coil enters the press machine and is pressed by the flat plate to form the colorful pressed roofing panels. Before the steel roof sheet is about to reach the sandwich panel laminating machine, it passes through the drip setting and screed setting for bonding the PU core material. At the same time, the red steel coil on the other side starts to be conveyed to the sandwich panel laminating equipment, and at the same time, its glue is evenly spread over the steel flat plate by the glue dripping setup and screeding setup on the other side as well. According to the program, the upper steel plate and the bottom steel roofing plate and PU core material enter the sandwich panel composite equipment at the same time, after heating and pressurization, the PU roofing sandwich panel is produced, when it reaches the pre-designed length, the shearing machine cuts it, and a qualified PU roofing sandwich panel is produced.