Mobile: 8613421351153

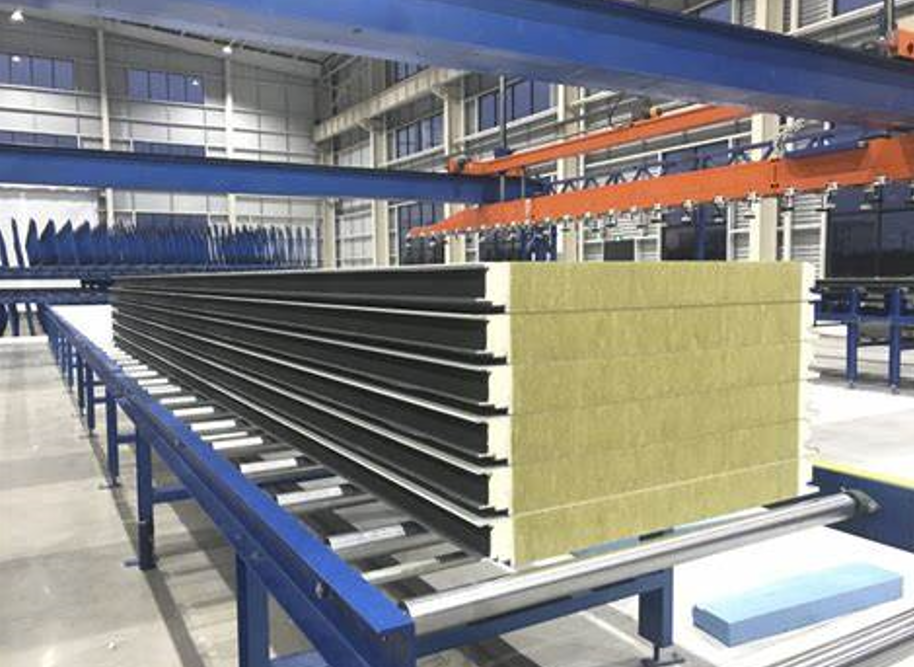

What is Rock Wool Sandwich Panel With PU Edge Sealing

Rock Wool Sandwich Panel With PU Edge Sealing is a newly developed sandwich panel that absorbs the advantages of rock wool and PU to become a popular sandwich panel for industrial buildings.

What is PU edge rock wool sandwich panel

Rock Wool Sandwich Panel With PU Edge Sealing is a non-combustible structural rock wool as the core material, galvanized or aluminium-zinc-coated color-coated steel sheet as the finish, polyurethane edging at both ends, and through the professionally developed adhesive, the two form an interactive composite of high-quality, energy-saving building panels.

Rock Wool Sandwich Panel With PU Edge Sealing is now internationally recognized as the best building enclosure fire insulation building materials. Its thermal conductivity is low. Good load resistance, high flexural strength, non-absorbent, non-rotting, non-insects and rodents, good flame retardant, large temperature range. Using the physical properties of polyurethane (PU, PIR) and unique formula, the polyurethane foaming agent evenly sprayed on the color coated steel plate, so that the foaming agent in the color coated steel plate between the foam molding to become a three-layer one-time molding of polyurethane (PU, PIR) color steel composite sandwich panel.

Advantages of Rock Wool Sandwich Panel With PU Edge Sealing

Polyurethane double-sided sealing rock wool sandwich panels give full play to the unique properties of rock wool core materials and have significant effects in fire prevention, thermal insulation, sound absorption and sound insulation, etc.; at the same time, they retain the plasticity, airtightness, high strength and non-absorbency of polyurethane the advantages.

Sealing performance

Polyurethane double side seal rock wool sandwich panel adopts the assembly line production process, thus using the excellent waterproof polyurethane products to overcome the shortcomings of rock wool easy to absorb water and moisture decomposition, in physical properties effectively extend the service life of the product.

Good thermal insulation

The thermal insulation of polyurethane double-side-sealed rock wool sandwich panels is based on the thermal conductivity of rock wool λ = 0.043W/M²K, calculated by the thickness of the corresponding proportion of rock wool core material.

Excellent fire protection

The raw materials, production process and formula used in the rock wool sandwich panel with polyurethane double-sided sealing make it have good fire resistance. Test surface shows that it has fire resistance exceeding 1000℃. The polyurethane double-sided sealed rock wool sandwich panel has passed the test of GIOROANO S.P.A, an authoritative Italian testing agency. According to the standards of the International Organization for Standardization (ISO), British BS and German DIN, the rock wool sandwich panel meets the fire protection M.I. Letter 14/09/61 91 and the requirements of D.M.30/11/83.

Highly effective sound insulation and absorption

Polyurethane double-sided sealed rock wool sandwich panels have a significant attenuation effect on noise transmission and are especially suitable for places where designated flights pass. In addition, after using rock wool roof panels, the indoor sound caused by the impact of rain and hail on the building’s roof steel panels is also significantly reduced. Through testing, in accordance with ISO 717/82 and UNI 8270/7 standards, a sandwich panel with a density of 120kg/m³ rock wool as the core material was selected, and the sound insulation effect can reach RW=29~30dB. The sound absorption performance level of rock wool sandwich panels reaches DELTA LA=15.7dB (A).

The advent of Rock Wool Sandwich Panel With PU Edge Sealing is a revolutionary change in construction engineering, which fully integrates the advantages of polyurethane and rock wool. Abandon the shortcomings of traditional boards. In a sense, PU edge rock wool sandwich panel cannot be compared with ordinary sandwich panels.