Mobile: 8613421351153

Why is the glass magnesium rock wool sandwich panels so popular

Glass magnesium rock wool sandwich panels are widely used, not only in building enclosure systems, but also in clean room systems. Why are it so popular?

What is glass magnesium rock wool sandwich panel

Magnesium glass panel, also known as fireproof composite panel, magnesium oxide panel, is to magnesium oxide, magnesium chloride and water ternary system, configured and added modifiers and made of magnesium, stable performance of the magnesium cementitious materials, alkaline fiberglass mesh as a reinforcing material to lightweight materials for the filler composite of the new non-combustible decorative materials.

Glass-magnesium rock wool sandwich panels are made of A-grade fireproof rock wool made of basalt as the internal core material, combined with glass-magnesium materials, and then cured. Not only does it have better fireproof performance, but it also increases the flatness and compressive strength of the panels.

4 advantages of glass magnesium rock wool sandwich panels

Glass magnesium rock wool sandwich panels have excellent physical and chemical properties. Light weight, high strength, fire-proof, non-toxic, tasteless, no radioactive pollution, high temperature resistance of 1200 degrees and non- combustion. Magnesium plate also has the properties of good toughness, no fracture, no separation from layers, high strength, sound insulation, heat insulation and no deformation.

Fire protection

Glass-magnesium rock wool sandwich panel is made of a combination of glass-magnesium board and rock wool core material, and the glass-magnesium board itself has a certain fire-resistant performance. And the built-in rock wool core material, using natural volcanic rock, is a noncombustible building material fireproof material, making it has a very good fire resistance. Through the authoritative testing organizations for fire resistance limit testing, fire time 1.5 h.

Thermal insulation

Magnesium rock wool sandwich panel with excellent performance, heat transfer coefficient of 0.832W/㎡-K, can achieve high efficiency heat preservation.

Soundproofing

The superior soundproofing performance of the glass-magnesium board ensures a quiet and elegant living environment, and the sound-absorbing effect of the rock wool core material filled inside adds to the soundproofing effect. Its unique uniform pore structure is unmatched by other dense glass-magnesium panels.

Superior Structural Properties

Magnesium glass wool sandwich panels have excellent structural properties. Glass-magnesium rock wool sandwich panels have more strength and rigidity than normal glass-magnesium panels due to the filling of rock wool, with a bearing capacity of 1.494kN/㎡. Glass-magnesium rock wool sandwich panel can be used as both enclosure structure and load-bearing structure.

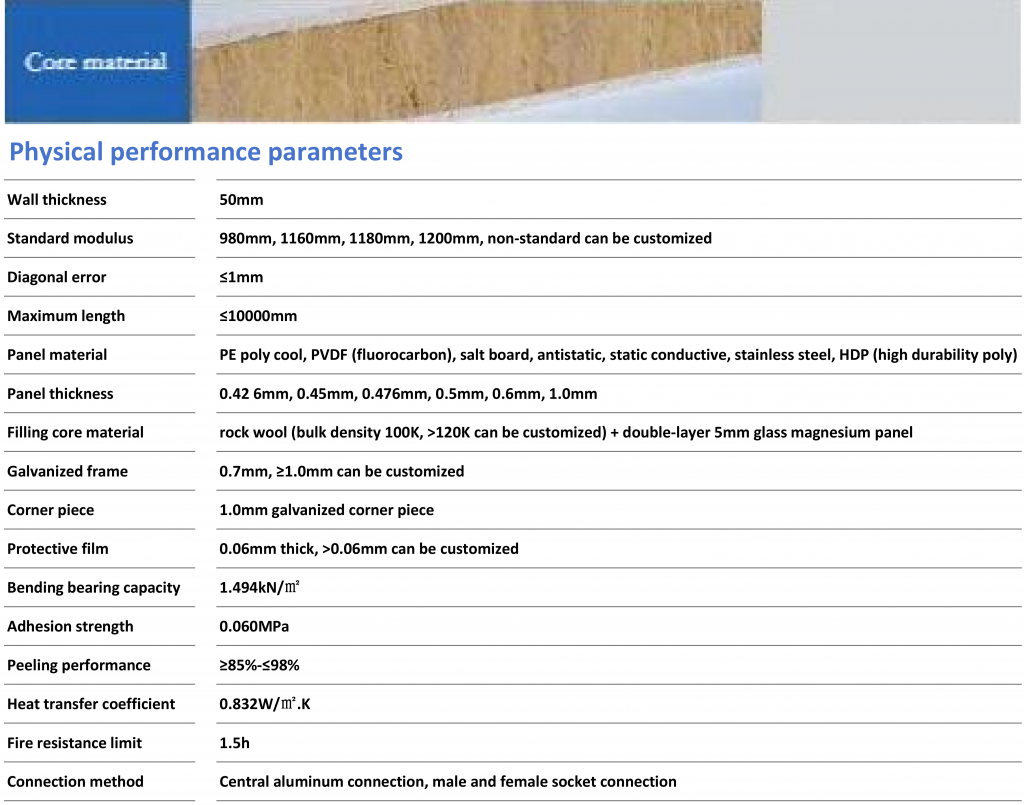

Performance of glass-magnesium rock wool sandwich panel

The following lists the properties of magnesium glass and rock wool sandwich panels with a thickness of 50 mm.

Glass magnesium rock wool sandwich panel have excellent physical and chemical properties. Light weight, high strength, fire-proof, non-toxic, tasteless, no radioactive pollution, high temperature resistance of 1200 degrees and non- combustion. Magnesium plate also has the properties of good toughness, no fracture, no separation from layers, high strength, sound insulation, heat insulation and no deformation.

These advantages make the glass-magnesium rock wool sandwich panel become a high quality sandwich panel favored by customers.