Mobile: 8613421351153

Everything You Need to Know About Cold room panels

Cold room panels, also known as cold storage panels, freeze room panels, are widely used in food, pharmaceutical and other temperature sensitive industries.

Introduction

The three important factors of the cold room panels are the density of the cold room panels, the thickness of the two side steel plate, and load bearing. Insulation panel density is relatively large, then to increase the amount of polyurethane, at the same time increase the thermal conductivity of polyurethane panel, so that the cold room panel insulation performance decline and increase the cost of the panel, if the density of the foaming is too low, will cause the cold room panels load-bearing decline, after the authority of the test general polyurethane cold room panels foaming density in the 35-43kg /m3 for the standard.

Selection of foam material for cold storage panels

There are two general types of foaming materials for cold storage panels: polystyrene foam and polyurethane. The choice of cold storage panel is very important for cold storage, because cold storage is different from other warehouses, cold storage on temperature, humidity and other environmental requirements are very high. So when choosing the cold storage panels, we should pay attention to the material of the panel and the strength of heat preservation.

Polystyrene cold storage panels

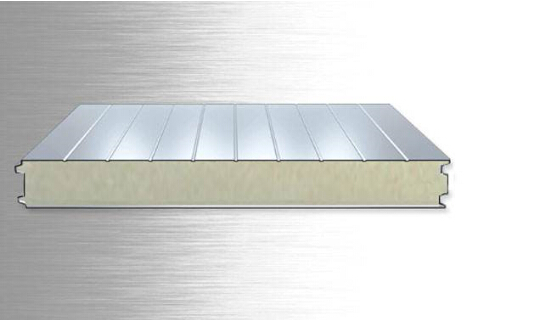

Polystyrene cold storage panel is made of pre-pained steel plate as the surface layer, closed-cell flame-retardant polystyrene foam as the core material, through the automated continuous molding machine will be pre-pained steel plate compression molding with high-strength bonding and become a kind of high-efficiency institutional materials.

Polyurethane cold storage panels

Polyurethane cold storage panel is a plywood type storage panel with good heat insulation performance of lightweight polyurethane as the inner material, the outside is composed of SII, PVC color steel plate, stainless steel plate, which can reduce the heat transfer due to the temperature difference between the inside and outside, in order to achieve the maximum efficiency of the refrigeration, freezing system.

Thickness of cold storage panel

The thickness requirement of cold storage panel is different for different cold storage. The thickness of the cold storage panel for high and medium temperature cold storage is generally not less than 100 mm, while the thickness of the cold storage panel for low temperature storage is more than 120 mm, and the thickness of the freeze storage panels is not less than 150 mm, and even reaches

In order to ensure the insulation quality of cold storage panels, procurement should pay attention to the density of the cold storage panels and the thickness of the steel plate, the thickness of the steel plate needs to be more than 0.4 mm, freeze storage panels of the thickness of the steel plate or even need to be 0.6 mm, the density of the cold storage panels per cubic meter in the 38 kg ~ 40 kg / m3.

SDpanel has gained a lot of experience in designing, manufacturing and supplying high quality cold rooms, freezers and refrigeration equipment, door panels and other related components. Whether it’s for food or laboratories, we offer cost-effective solutions based on the individual needs of our customers. Please let us know the details of your requirements such as room size, temperature, usage or your special requirements for budget or energy saving. We can design an efficient and cost-effective solution that is ready to meet all your requirements.