Mobile: 8613421351153

Joint design of sandwich panels

Sandwich panels, as the building envelope, are not as critical as the stressed members, but still have a pivotal importance to the structural system. The design of joints is an important part of the fixing or joining of these enclosures.

The joint design of sandwich panels mainly includes the tensile load capacity calculation and shear load capacity calculation of the joint.

Calculation of tensile bearing capacity

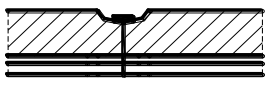

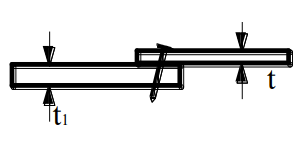

The tensile bearing capacity of the sandwich panel joint, in the absence of test data and when the thickness of the sandwich panel metal panel t satisfies 0.5mm≤t≤1.5mm and the thickness of the supporting member t1 satisfies t1≥0.9mm, may be determined as follows:

The tensile load capacity of metal panels

The tensile load capacity of metal panels shall be calculated according to the following equation:

a. the metal panel is steel:

F≤ktdwƒ ———–(1-1)

b. the metal panel is aluminum:

Notes:

dw ——-Diameter of fastener washer or nail head (mm)

ƒ ——–design value of tensile strength of metal panels (Mpa)

k ——–parameters, 1.1 for static load and 0.55 for reciprocating load;

t ———Thickness of metal panels (mm)

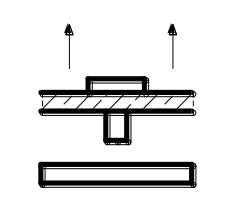

The support member pullout bearing capacity

The support member pullout bearing capacity shall be calculated by the following equation:

a. the metal panel is steel

F≤0.65t1dnƒc

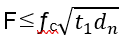

b. the metal panel is aluminum:

Notes:

dn ——- Nominal Diameter of Fastener (mm)

ƒc ——– Design value of tensile strength of supporting members (Mpa)

t1 ——— Thickness of support elements (mm), When t1 ≥6mm, take t1 = 6mm

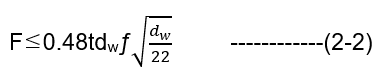

Calculation of shear bearing capacity

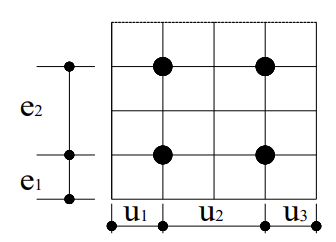

The shear bearing capacity of the sandwich panel joint, in the absence of test data, can be determined as follows when the fastener arrangement satisfies the conditions of Eqs. (2-1) to (2-4)

e1≥3dn ——-(2-1)

e2≥3dn ——-(2-2)

u1≥1.5dn ——-(2-3)

u2≥3.0dn ——-(2-4)

Of these, Among them, steel: 3.0mm≤dn≤8.0mm; Aluminium: dn≥5.5mm:

The bearing capacity for hole wall damage or fastener tilt failure

The bearing capacity for hole wall damage or fastener tilt failure can be calculated by the following equation:

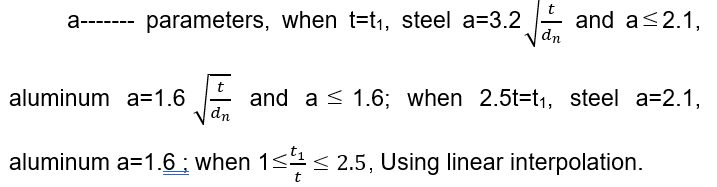

V≤adntƒ ——-(2-5)

Note:

The tensile capacity of the net section of the metal panel

The tensile capacity of the net section of the metal panel can be calculated according to the following formula:

V≤ Anƒ ——–(2-6)

Note:

An—— Net cross-sectional area of metal panels(mm2)

These are the joint designs of sandwich panels, which are emphasized in sandwich panel applications.