Mobile: 8613421351153

Mechanical properties of sandwich panel structure test content and calculation methods

According to MIL-STD-401B or ASTM C-393, the testing of sandwich panel construction consists of the following parts:

- Long Beam Flexure Test

- Edgewise Compression Test

- Flatwise Tension Test

- Flatwise Compression Test

- Short Beam Shear Test

- Climbing Drum Peel Test

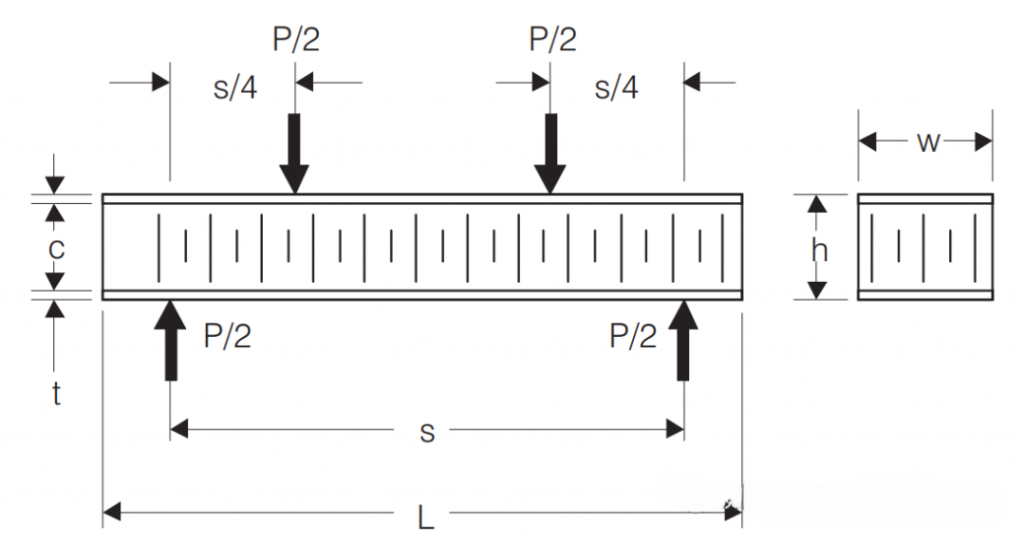

Long Beam Flexure Test

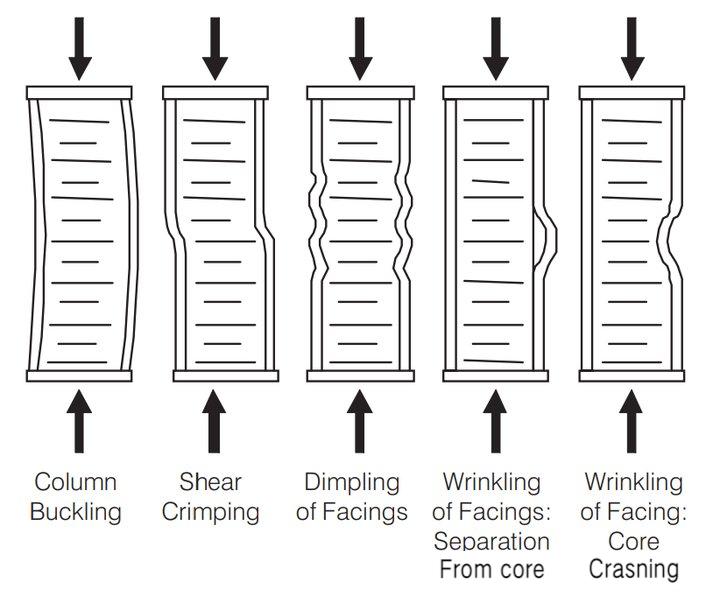

There are several possible failure modes for this test (see Figure 1), and some of the more typical failure modes include cortical tensile/compression damage, localized facial wrinkling failure, and localized facial defects.

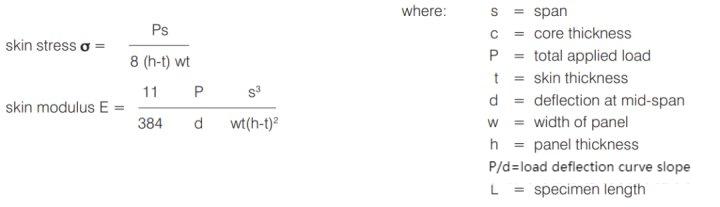

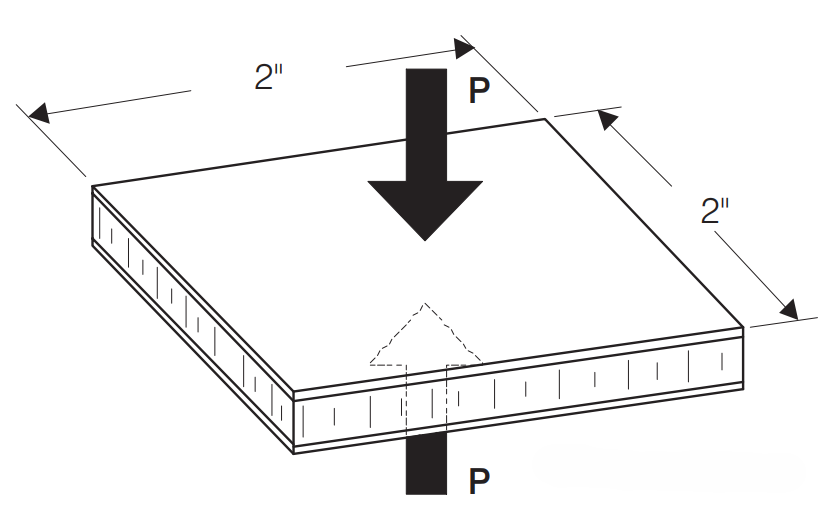

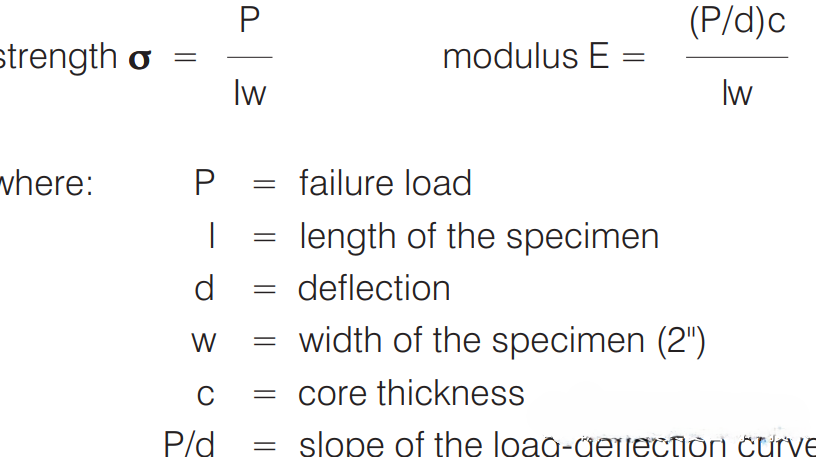

The typical span of the long beam bend test is 20 inches. The long beam bend test can determine the sandwich flexural strength and flexural modulus. The average skin stress and modulus can be determined using the following formula:

The above calculation formula is applicable to symmetrical sandwich panels with thin skin structures. For more details on tests and data, please refer to Section 5.2.4 of MIL-STD-401B or ASTM C-393.

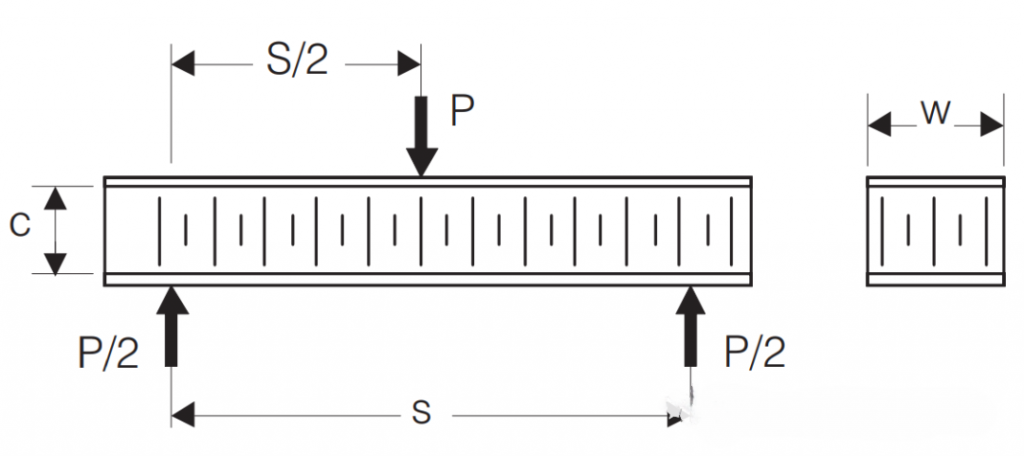

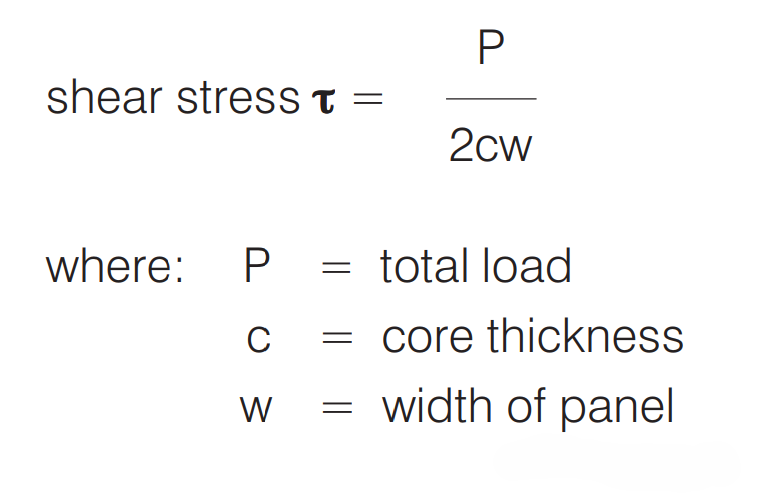

Short Beam Shear Test

The typical span for this test is 4 inches (see Figure 2). Although there are several possible failure modes for this test, the typical failure mode is core structural failure.

In the short beam bending test, if the core is damaged, the core shear strength (average shear stress) can be calculated as follows:

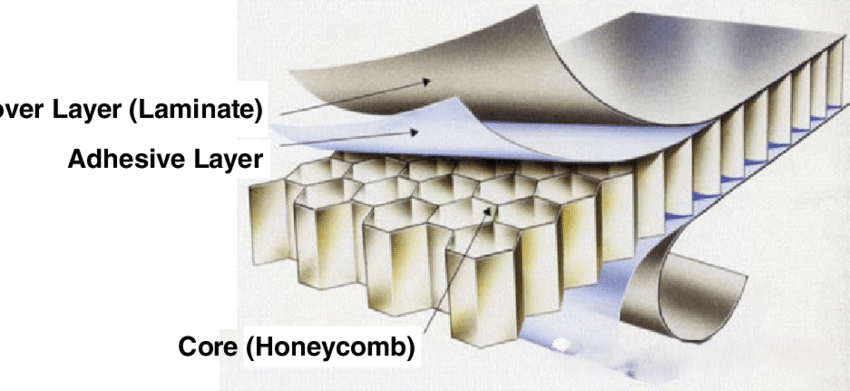

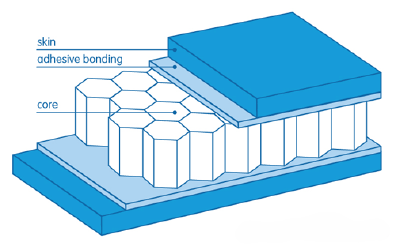

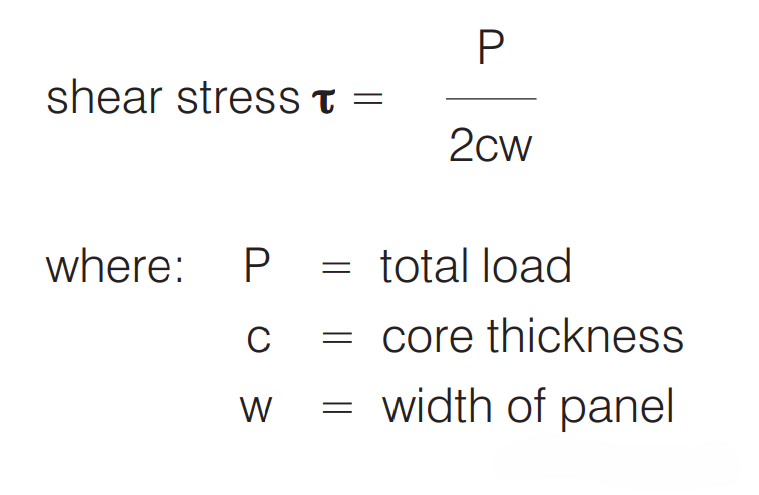

Flatwise Compression Test

This test method is mainly applicable to sandwich panel structures with thin skins. For detailed explanation and discussion of the test and data, please refer to MIL-STD-401B Section 5.2.4 or ASTM C-393.

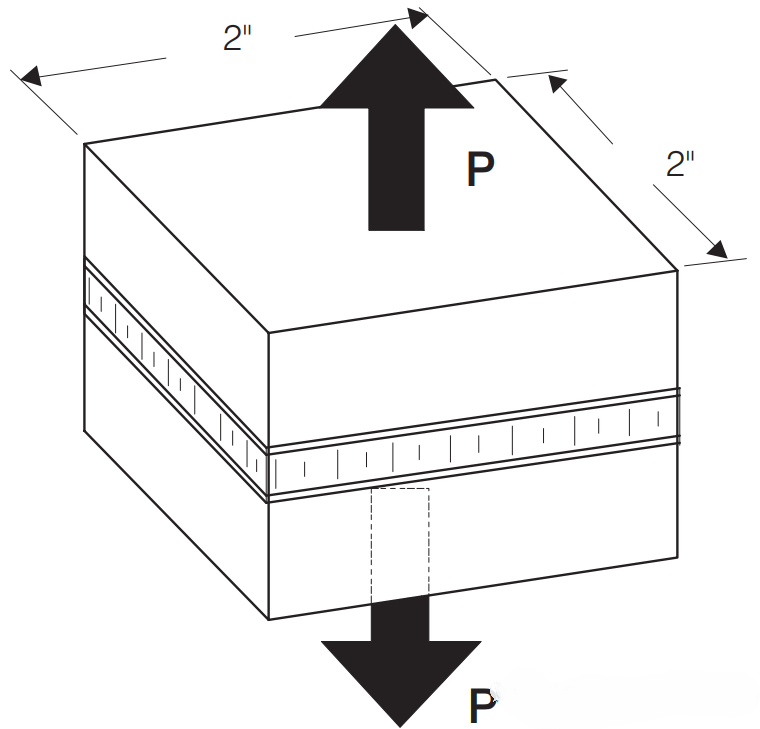

The primary objective of the flat compression test for sandwich panels is to determine the core compression performance of the sandwich panel. A typical sample for this test is a 2 x 2 inch panel as shown in the figure.

From the complete load-deflection curve during testing, the compressive strength and compressive modulus of the core can then be determined using the following equations:

Flat Tension Test

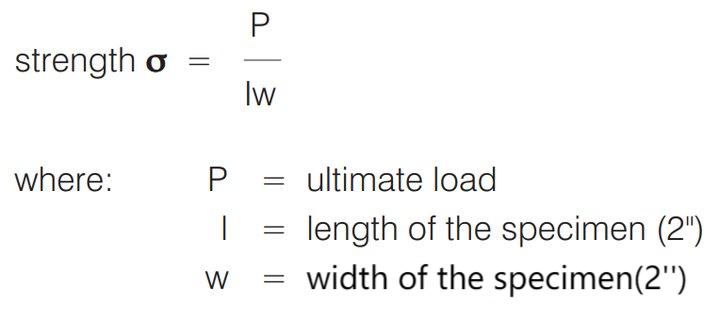

The purpose of this test is to determine the tensile strength of the core material or the peel skin-core bond strength. The test is performed on two 2×2 inch specimens, which are glued between heavy metal load blocks and then pulled apart in a testing machine (see Figure ).

The average horizontal tensile strength of the interlayer can be calculated by the following formula:

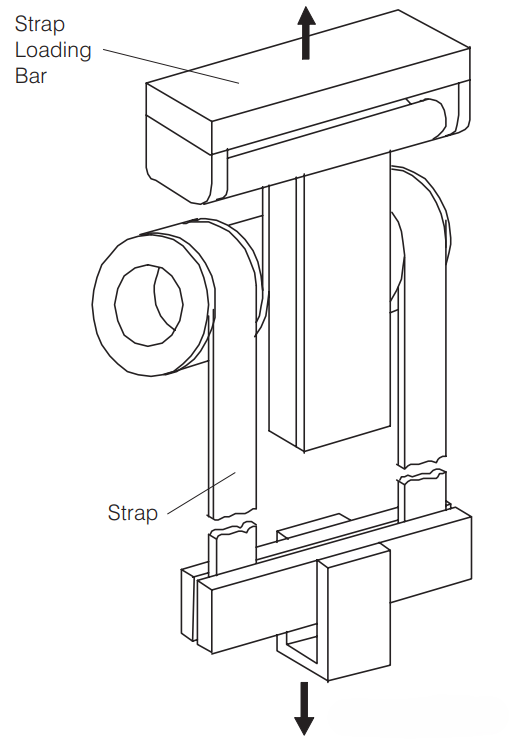

Edgewise Compression Test

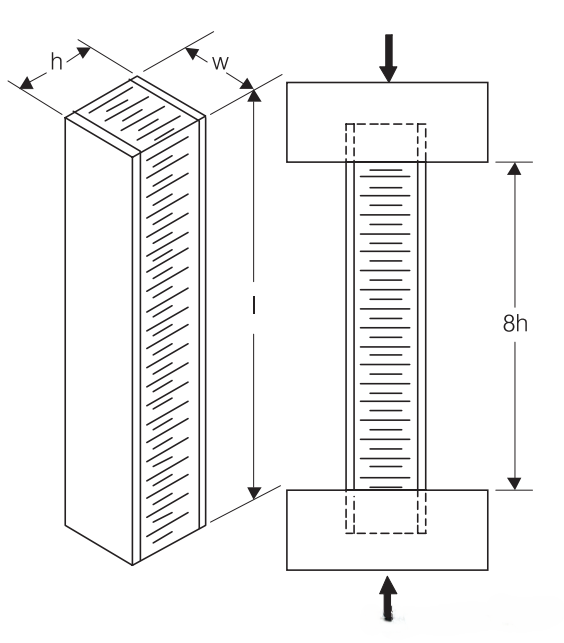

This test is mainly used to determine the load-bearing capacity of sandwich panels in their face sheets, and the test diagram is shown in Figure . The typical size of the specimen is at least 2 inches wide, and the unsupported length should be at least 8 times the thickness of the sandwich.

There are several possible failure modes for this test such as column buckling, shear crimping, and surface depression (see Figure 6). Due to the nature of this test, additional care should be taken to ensure that the specimen has a good flat end to prevent premature failure of the specimen end. Casting the ends with an appropriate molding material is permitted according to ASTM C-364, which helps prevent premature end crushing failure modes.

During testing, extreme care should be taken to ensure that the specimen is straight and parallel to the direction of loading, which will help prevent premature column buckling failure modes. Column buckling failure modes generally represent column instability rather than a measure of surface load carrying capacity. Therefore, every effort should be made to prevent this failure behavior.

In addition, strain gauges should be used to monitor the strain on both surface skins during the early stages of the test. The tension on both sides of the skin should be 10% of each other, indicating that the results are very different due to different effective eccentricities. The average edge compression strength can be determined by the following formula:

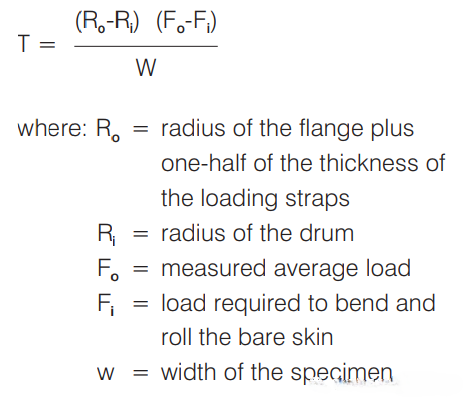

Climbing Drum Peel Test

This test method is intended to determine the debonding resistance of the adhesive between the skin and core of a sandwich panel (see Figure ). The specimen should be at least 10 inches in length and typically 3 inches in width.

As the test progresses, an average constant torque level will be reached to peel the adhesive. However, this torque level includes the amount of torque required to roll off the bare skin, so this level should be determined in advance and then subtracted from the actual reading to give a valid measure of the adhesive strength. The average peel torque can be calculated using the following formula: