Mobile: 8613421351153

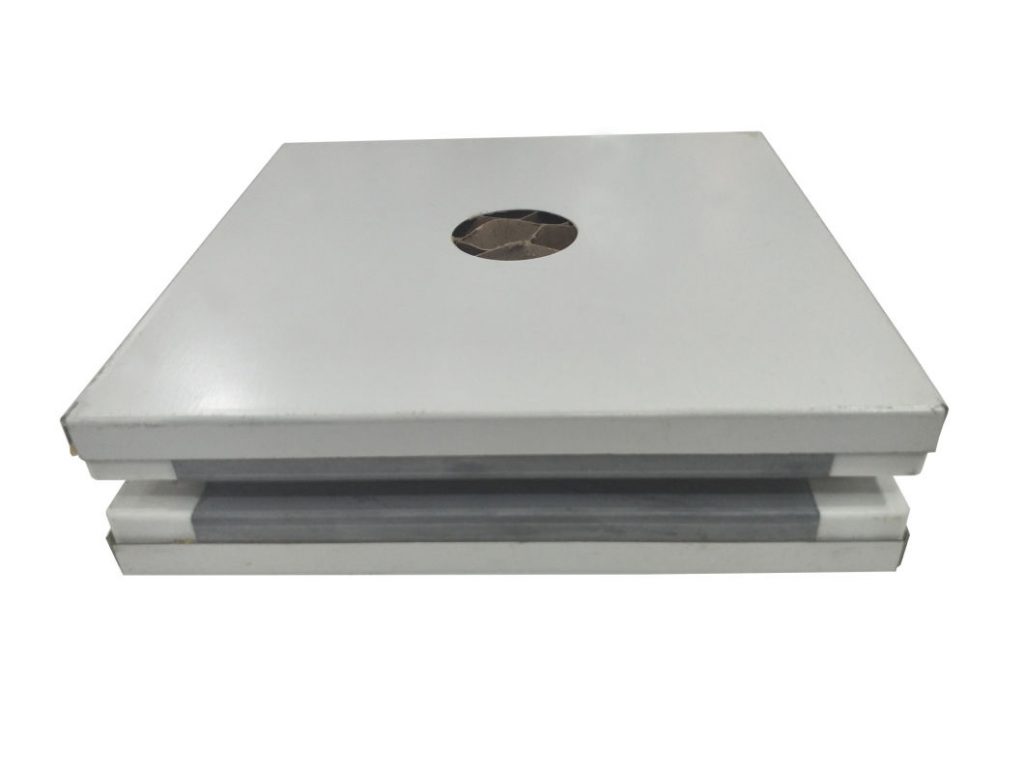

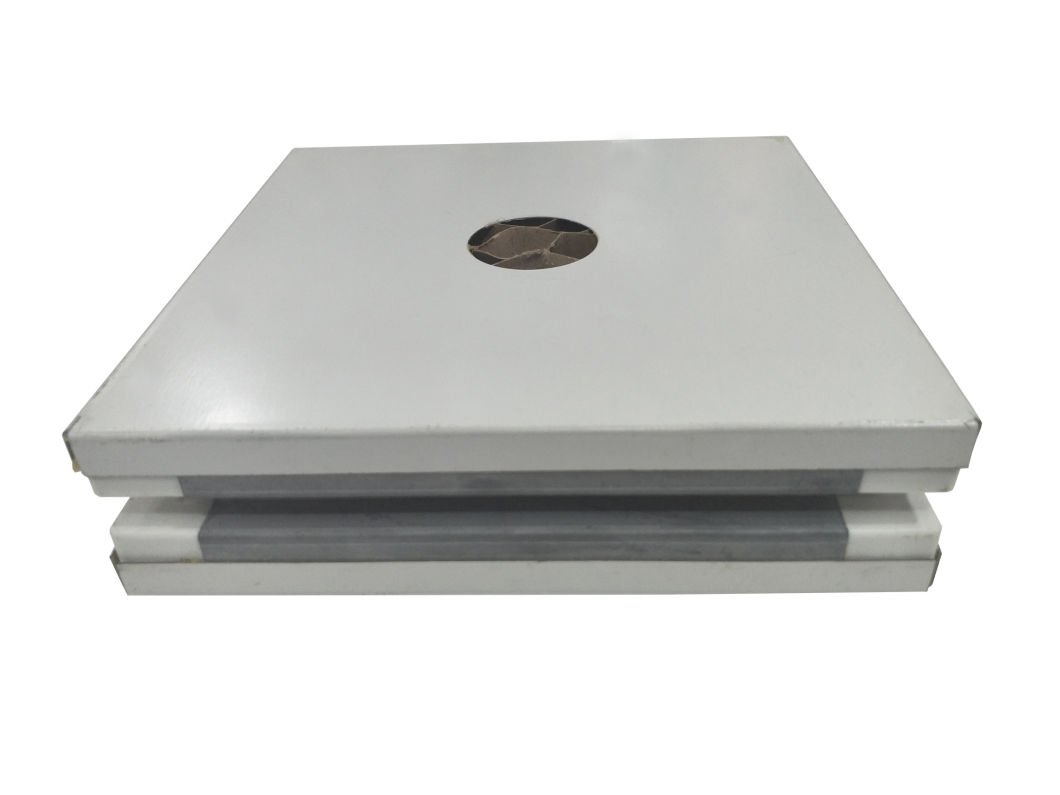

What is Paper Honeycomb Panels

Paper honeycomb panels are ultra-light building panels made of colored coating as the panel and paper honeycomb as the core material, which are compounded by heating and pressurizing in a continuous molding machine with heat-curing glue.

Specifications and performance of paper honeycomb sandwich panels

- The pore sizes of paper honeycomb sandwich panels are generally 8 mm, , and 32 mm, and the density of paper honeycomb panels is 28 kg/m2.

- Paper honeycomb sandwich panels width: 950 mm, 1150 mm Thickness: 50 mm, 75 mm, 100 mm, 150 mm, 200 mm.

- Steel plate: thickness 0.4~1.2 mm, material: colored steel plate, stainless steel plate.

- Paper honeycomb sandwich panels often adopt tongue-and-groove insertion, which is easy to install and has good flatness.

- Paper honeycomb sandwich panels are connected to the roof trusses with hidden self-drilling screws, which does not damage the exposed part of the color-coated board, prolonging the life of the sandwich panels. The connection between the boards adopts a buckle cap type, which is convenient for construction, improves efficiency, and is not easy to seep water.

- The core material of the paper honeycomb sandwich panel is made of black and other natural minerals as the main raw materials, which are melted into fibers at high temperature, added with an appropriate amount of adhesive, and solidified.

Advantages of Paper Honeycomb Panels

1. Lightweight, less material, and low cost. Compared with other types of plate structures, the honeycomb sandwich structure has a high strength-to-weight ratio, so its finished products are cost-effective. The density of ordinary honeycomb paperboard is about 25~50 kg/m3, which is 1/3 of the density of common corrugated paperboard. The price of ordinary honeycomb paperboard is only 60% of wood, 50% of steel, and 66% of heavy seven-layer corrugated paperboard, which can bring better economic benefits to users.

2. High strength, smooth surface, and not easy to deform. The honeycomb board sandwich structure is approximately isotropic, with good structural stability and not easy to deform. Its outstanding compressive and bending resistance are important characteristics required by paper honeycomb boards. The front of ordinary honeycomb paperboard can withstand a pressure of 2-5kg per square centimeter, which is 5-10 times the compressive resistance of ordinary corrugated paperboard. The bending strength of ordinary honeycomb paperboard is 2-5 times that of reinforced corrugated paperboard and 5-30 times that of ordinary corrugated paperboard.

3. Good impact resistance and cushioning. The honeycomb panel is made of flexible paper core and paper, with good toughness and resilience. The unique honeycomb sandwich structure provides excellent cushioning performance and has a higher energy absorption value per unit volume among all cushioning materials.

4. Sound absorption and heat insulation. The honeycomb panel sandwich structure is a closed chamber filled with air, so it has good sound insulation and heat preservation performance.

5. No pollution, in line with modern environmental protection trends. The honeycomb panel is made entirely of recyclable paper materials and can be recycled and reused after use. Even if it is discarded, it can be naturally degraded and absorbed, and is a good green environmental protection material.